Damping and relief systems reduce explosion effects to a safe level, thus protecting the plant against destruction. Nevertheless, residual explosion effects in the form of a wave of fire and pressure may spread through a system of pipes, ducts and conveyor transfers to neighbouring facilities.

This phenomenon leads to generation of secondary explosions which bring about much worse effects. In extreme cases, this may lead to a complete destruction of process plants. To counteract this phenomenon – in compliance with the Polish and European law – explosion decoupling (cut-off) systems must be applied. It is aimed at closing physically the pipelines, ducts and conveyor transfers that connect the explosion-affected facility with the remaining parts of the plant.

Delivery range

VigiFLAP non-return damper

As the only explosion-proof non-return damper on the market, it can be placed on vertical pipes and on the clean side of filters, effectively isolating the explosion. This is possible thanks to the use of technology that keeps the damper open until the explosion spreads. In the event of an explosion, the valve closes and remains locked, preventing the spread of the explosion and flame. The damper must be unlocked manually. Additionally, the VigiFLAP has a certificate for metal dusts.

SNR non-return damper

The SNR non-return damper is a simple and cost-effective solution for isolation of an explosion origin by closing the ductwork and preventing further propagation of explosion to the remainder of the protected installation.

Extinguishing cylinders type HRD

Application: explosion protection of equipment units (including silos, filters, cyclones, mixers, drying plants, pelleting machines, etc.) in presence of flammables at explosive concentrations levels. The HRD cylinders provide explosion protection for processing equipment units, vessels, and ductwork which contain class ST1 to ST3 particulate matter, gases and/or hybrid mixtures in all industrial sectors.

ATEX-certified rotary valves

ATEX-certified rotary valves (also known as rotary dispensers) are applied as feeding dispensers for bulk products and airflow-reduction gates in dust extraction systems, central vacuum cleaning systems, pneumatic handling systems, and in similar applications. If certified for compliance with ATEX 95, the rotary valves are approved for use in Ex-zones and as standalone explosion isolation systems.

VENTEX ESI explosion isolation valves

The VENTEX explosion isolation valves are available in a wide variety of sizes and versions for passive explosion isolation. The valve is intended for installation in the ductwork of dust extraction / separating systems, positive or negative pressure handling systems, drying systems, or granulation systems. In most cases, the valves are resistant to the maximum explosion pressure.

Speed WEY HSI explosion isolation gate valves

The Speed WEY HSI explosion isolation gate valves are most robust, heavy-duty explosion isolation systems. The operating principle is similar to knife gate valves, but the trigger response and closing times are extremely short.

ExKop explosion isolation system

While being a rather unusual solution, this explosion isolation system provides two unique features. First, the explosion isolation valve can be triggered to close by a decompression panel opening system (in the explosion venting system) or a dedicated IR sensor. Second, the explosion isolation valve can be reset for repeated use after an explosion.

ATEX-certified pressure rotary lock

A pressure rotary lock is a system of two rotary valves interconnected by a pressurization chamber. The pressure rotary locks enable pressure-less feeding or discharge of powders or liquids to or from positive-pressure or vacuum-pressure areas. If ATEX 95 certified, the pressure rotary locks can be operated in Ex-zones or as standalone explosion isolation systems.

Scope of works

- Selection of an optimum decoupling system;

- Delivery and installation (of mechanical and electrical components);

- Inspection and servicing.

Classification of explosion decoupling systems based on their mode of operation

| EXPLOSION DECOUPLING SYSTEMS | PASSIVE | ACTIVE |

|---|---|---|

| FLAME CUT-OFF | HRD cylinders | |

| PRESSURE CUT-OFF | Non-return dampers | |

| FLAME AND PRESSURE CUT-OFF | Dosing valves | Gate valves |

| VENTEX® valves |

- Passive systems are powered by the energy of the spreading explosion. They will activate precisely when the pressure wave or fire reaches the protection.

- Active systems rely on sensors that detect an explosion. In such a situation, a signal is sent to the disconnecting device to activate it.

The destructive force of secondary explosions, or why they must be prevented

Secondary explosions often pose a significantly greater threat than the primary explosion. This is because their maximum pressure and dynamics are higher. This can lead to the rupture of the apparatus in which the secondary explosion occurred, even if explosion protection measures such as venting or explosion suppression were applied.

A secondary explosion starts at a higher pressure than a primary one. Additionally, the pressure wave from the primary explosion causes turbulence in the dust-air mixture in the installation, accelerating combustion. There is also a stirring up of settled dust in the installation and dust present in the apparatus. If the concentration of dust particles increases but does not exceed the optimal level, dust ignition becomes easier. All these factors caused by the pressure and fire wave from the primary explosion mean that these waves eventually encounter an explosive atmosphere with a high concentration of explosive dust. The fire wave, which in this case is the ignition source, has a much larger surface area and energy than a small spark or hot surface that caused the primary explosion.

In such a situation, explosion protection measures become ineffective, and the secondary explosion has a much greater impact than the primary one. This can lead to catastrophic damage. On August 4, 2020, the world’s eyes turned to Beirut. Although the explosion did not occur in an industrial plant but in a neglected warehouse with 2,750 tons of accumulated ammonium nitrate, it is a tragic, extreme, yet perfect example to realize the scale of destruction that can occur in a secondary explosion. Just as the primary explosion destroyed part of the warehouse, the secondary explosion leveled most of this two-million city.

Active systems: It is crucial to determine the installation location of the explosion decoupling system

The key issue for systems that must first detect an explosion to act and stop it is to choose the right installation location for such a system. The system must act before the explosion reaches the system’s installation location. Remember that a primary explosion can occur in different parts of the apparatus. Both the explosion can take place near the pipeline, inside the apparatus, and on the other side. This means that depending on the location of the explosion, pressure and flame waves will cover different distances in the same time.

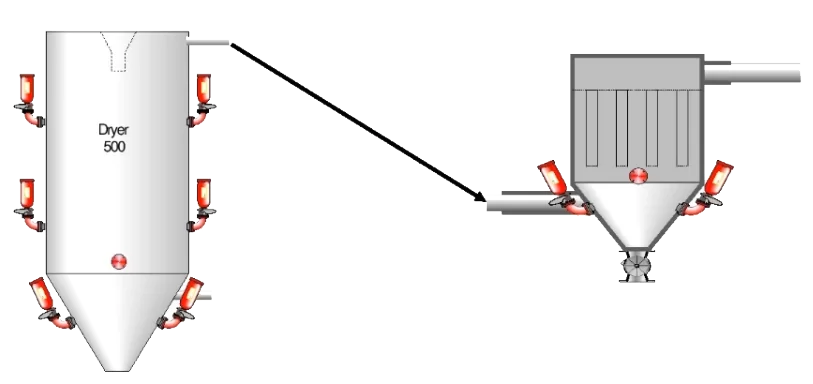

Let’s see the example: How to protect apparatuses using HRD cylinders?

Short distance = like one device

For short pipeline distances between devices, the use of explosion decoupling is essentially not possible. Both devices should be treated as one system in terms of protection, and regardless of which apparatus the explosion occurs in, protections on both apparatuses must be activated.

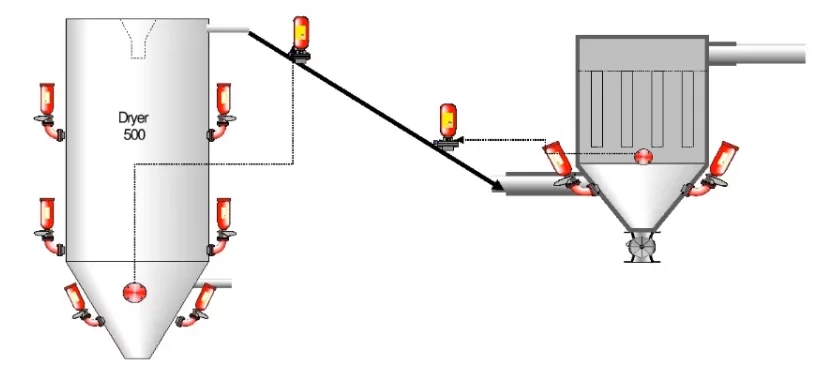

Slightly greater distance = 2 HRD cylinders

For slightly greater pipeline distances between devices, it is possible to use 2 cut-offs. The logic is that when an explosion occurs in one device, the HRD cylinder near the second device is activated so that the suppressing powder can be injected into the pipeline before the explosion reaches the cut-off point.

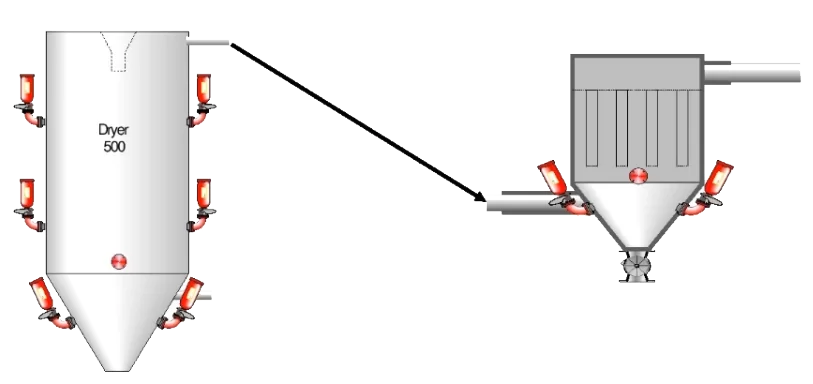

Even greater distance = 1 HRD cylinder

For greater distances, but below the distance threatening detonation in the pipeline, a single decoupling is used between the devices.

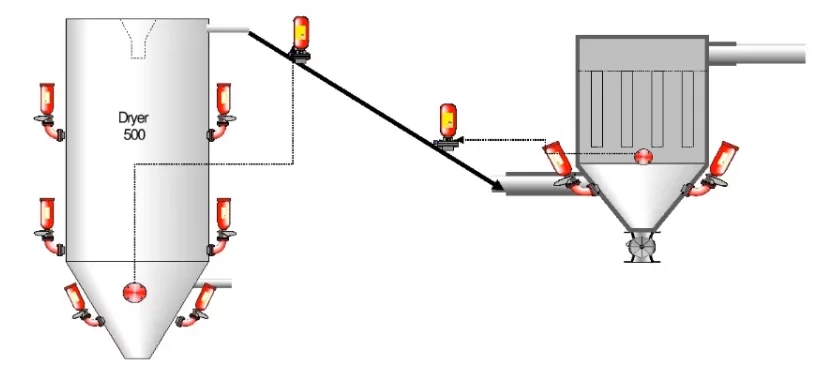

Distance threatening detonation in the pipeline = 2 HRD cylinders

For large distances, above the distance threatening detonation in the pipeline, two cut-offs are used on the pipeline. In this case, the HRD cylinder closer to the device where the explosion occurred is activated. This not only protects the second device but also the pipeline itself.

Active systems: It is crucial to determine the installation location of the explosion decoupling system

The key issue for systems that must first detect an explosion to act and stop it is to choose the right installation location for such a system. The system must act before the explosion reaches the system’s installation location. Remember that a primary explosion can occur in different parts of the apparatus. Both the explosion can take place near the pipeline, inside the apparatus, and on the other side. This means that depending on the location of the explosion, pressure and flame waves will cover different distances in the same time.

Let’s see the example: How to protect apparatuses using HRD cylinders?

Short distance = like one device

For short pipeline distances between devices, the use of explosion decoupling is essentially not possible. Both devices should be treated as one system in terms of protection, and regardless of which apparatus the explosion occurs in, protections on both apparatuses must be activated.

Slightly greater distance = 2 HRD cylinders

For slightly greater pipeline distances between devices, it is possible to use 2 cut-offs. The logic is that when an explosion occurs in one device, the HRD cylinder near the second device is activated so that the suppressing powder can be injected into the pipeline before the explosion reaches the cut-off point.

Even greater distance = 1 HRD cylinder

For greater distances, but below the distance threatening detonation in the pipeline, a single decoupling is used between the devices.

Distance threatening detonation in the pipeline = 2 HRD cylinders

For large distances, above the distance threatening detonation in the pipeline, two cut-offs are used on the pipeline. In this case, the HRD cylinder closer to the device where the explosion occurred is activated. This not only protects the second device but also the pipeline itself.