Plunger Heater | ATEX – gas / dust zone | RFA type

A plunger heater type RFA in a flame-proof enclosure. This device is ATEX, IECEx, CSA, CU TR, KGS, CNEx, CCOE, and Inmetro certified. Heaters of this type are designed for heating up process media. They are used in process tanks, including pressure tanks and other equipment located in gas and dust explosion hazard zones. The heater can be installed vertically or horizontally (optional), using a threaded or flanged connection.

We will answer questions about: offer, technical specification, delivery, assembly.

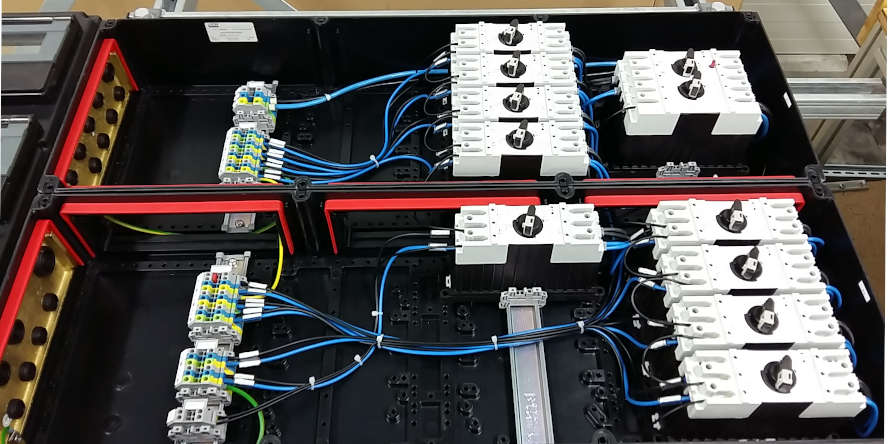

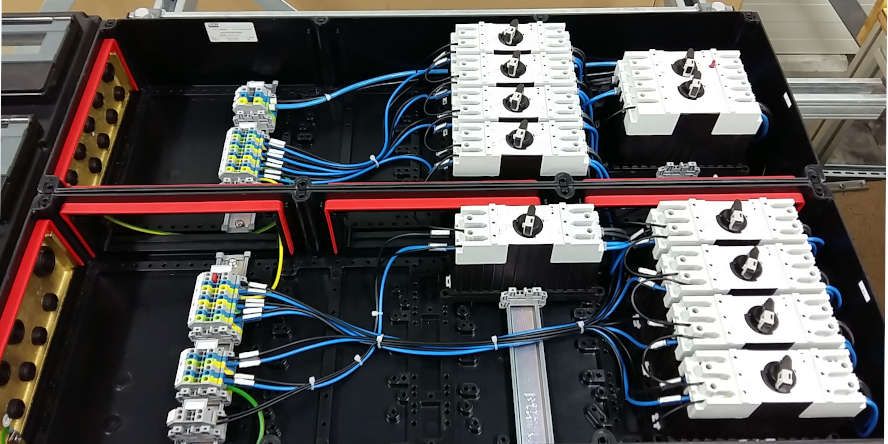

The RFA electric cartridge heater can be used in explosion hazard areas 1 and 2 for gases or vapours (ATEX certified). The standard version of the device can be powered from any power source up to 690V (600V CSA). In addition, the heater is equipped with a robust terminal box, which ensures easy connection and protects the electrical connection. The design of the device enables its quick installation in the production line (it is installed using a threaded flange).

The heater is designed for long-term operation in harsh conditions (IP66 and IP67). Its durable housing is made of soft steel (optionally stainless steel) with powder coating (optionally with epoxy paint). The equipment of this series is designed for heating up various types of media in process tanks and other types of equipment requiring heating up of the medium. The heater can be powered from a single-phase, three-phase power supply, or with direct current. Its design makes it possible to eliminate the heating element and diagnose it without emptying the system.

The heating element is a high quality nickel-chromium (80/20) resistance wire. It is enclosed in a stainless steel mantle made of INCOLOY® Alloy type 800, 825 or 316L, 304 or 321, the inside of which is filled with magnesium oxide powder – it serves as electrical insulation and a very good thermal conductor. The whole unit is protected by solder or weld.

The device is delivered equipped with one input for 20mm diameter cable and one 25mm input. In addition, the standard version includes protection against overheating of the device, and external and internal earthing systems.

The heater is designed to operate in an ambient temperature from -40oC to +40oC.

- Installation: Use a threaded hub or a standard industrial flange

- Voltage: up to 690V

- Power: 12kW (for water applications) and up to 3kW (oils)

- Housing material: powder-coated aluminium

- Heating element: high quality resistance wire (nickel-chromium) in a ribbed housing, made of INCOLOY® Alloy type 800, 825 or 316L,304 or 321, filled with magnesium oxide powder

- Control: the thermostat is designed for use in explosion hazard atmospheres (optionally)

- IP rating: 66, 67

- Ambient temperature: -60ºC to÷ +60ºC

- Additional protection with thermostats

- The housing finished with epoxy paint

- The heater is adapted for installation in vertical piping

- The heater’s housing is made of stainless steel

- Additional sensors for temperature measurement available on request

- process tanks

- safety showers

- engine oil sumps

- pressure vessels

- ATEX

II 2 G

II 2 G - Ex d IIC T3 to T6 Gb Zone 1 and 2

- CU TR (EAC)