Screening Machines

We deliver vibrating screens, screening conveyor troughs, air separators and on-line granulation measuring devices. Our services include both selection of equipment (which can be effected on the basis of tests with the actual product), as well as its installation, commissioning and service.

The equipment offered operates in tens of production plants and among our customers, there are food industry companies, chemical plants, manufacturers of construction chemical products and aggregates.

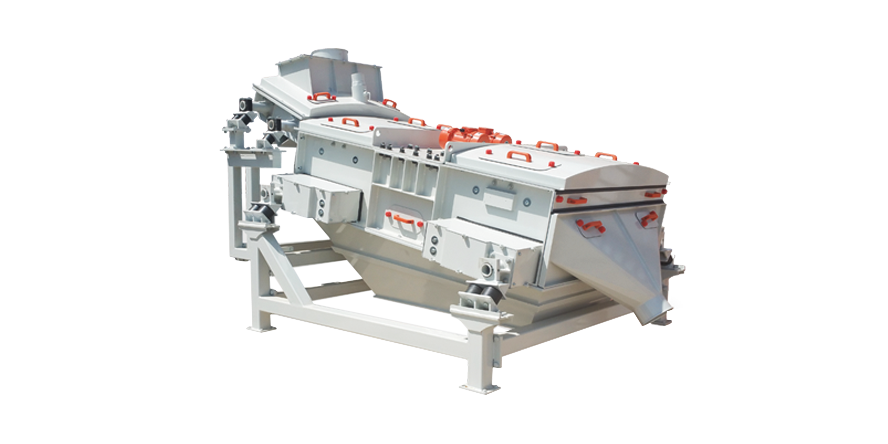

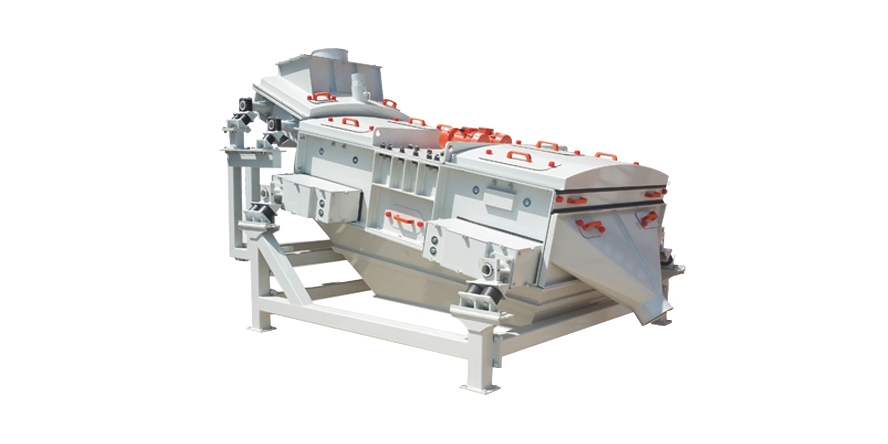

Screening machines for fine-grained products and medium-grained products

We deliver both screening installations and autonomous screening machines for loose and wet products with granulation up to 30 mm. Thanks to the patented VFE® (Vibro-Flex Exciter) actuators, the screening cloth vibrates with chaotic frequency, which translates into a series of quite significant advantages. To the most important advantages of our products belong exceptionally high quality of screening wet and very fined-grained products with fraction of 200 µm that have a tendency to screen clogging effect (possibility to separate the product even at the cut point of 36 µm).

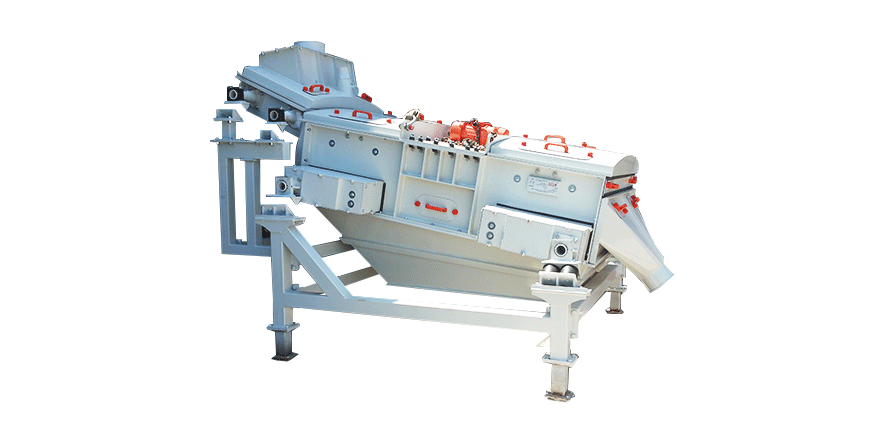

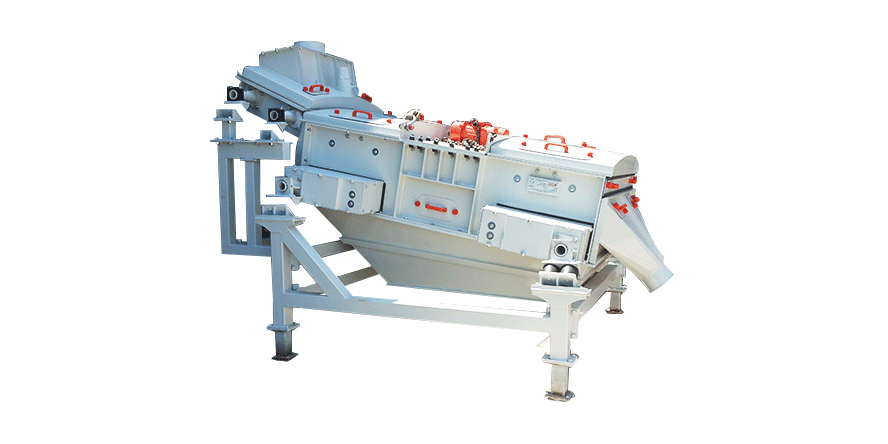

Dewatering screening machines

We deliver dewatering screening machines for products with granulation up to 30 mm, which are characterised by both loose and tight, silty, and even loamy structure. Dewatering screening machine is perfect for dewatering of suspensions, separating of solid fractions, and wet screening of fine-grained fractions, including loamy and silty fractions.

Screening machines for wet screening

We deliver screening machines for wet screening of products with granulation up to 30 mm. In screening machines for wet screening, the product fed to the screen is rinsed with water sprayed from jets located above the screen deck. Wet screening is perfect for applications, when the material used for production possesses clay-loam contamination that may agglomerate product grains and as a result prevent their screening. Therefore, it may have a negative effect on the product’s quality, as well as on later crushing, drying or screening processes.

Air Classifier

We provide air classifiers or complete lines for milling and segregating loose products. The capacity of a single air separator is in the range of 0.8 to 80 t/h. Then the milling lines, apart from the air classifier, also include systems for transporting and feeding the product to the mill, weighing system, pneumatic system for receiving the milled product, dedusting and screening plants. The offered solutions are operated in hundreds of industrial plants throughout the world, in particular in the production of cement, clinker, ceramic semi-finished products, kaolin, bentonite, coal, coke, dolomite, talcum, anhydrite, calcite and limestone.