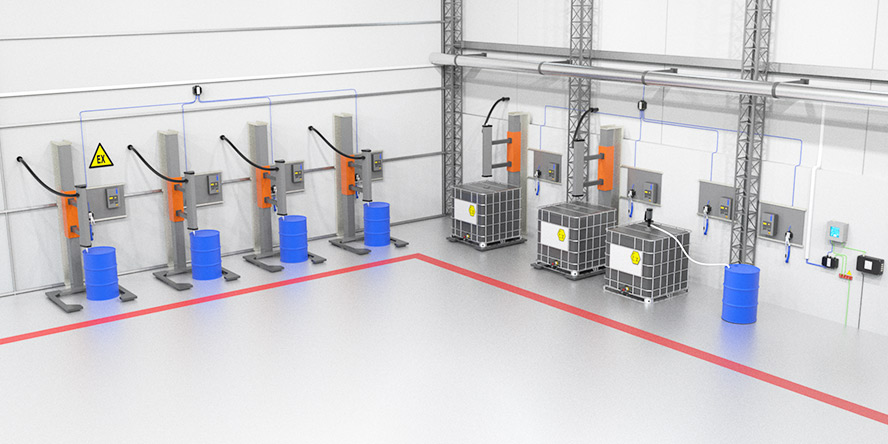

Electrostatic earthing

Electrostatic earthing systems reduce the risk of explosion of inflammable substances as a result of electrostatic flash-over. They are applied during transport and processing of inflammable gases, liquids and powders. Simple earthing systems consists of a conductor and an earthing clamp, more advanced ones have an earthing state control system that allows for transport/dosing of product only when the earthing has been properly connected. Earthing systems are usually applied for loading/unloading road and railway tankers, drums, tanks, big-bags, process plant elements, etc.

Functions performed | Grounding control systems with process interlocking | Grounding control systems with process interlocking dla wielu urządzeń | Clamps with grounding control | Terminals, wires, reels |

|---|---|---|---|---|

| Charge discharge (grounding) |

|

|

|

|

| Grounding clamp break check |

|

|

|

|

| Breakthrough check through paint, rust and dirt |

|

|

|

|

| Checking for damage to the ground cable |

|

|

|

|

| Checking whether charges are discharged into the ground |

|

|

|

|

| Process interlock in the absence of grounding |

|

|

|

|

| Checking that the clamp has been connected to the road tanker |

|

|

|

|

Earth control systems with process lock (tanks, big bags)

Below you will find a list of dedicated technical solutions of Earth-Rite series in the field of earthing monitoring of e.g. road tankers, railways, big-bags, as well as components of process plants. Earth-Rite systems verify easily and safely that the stored loads are properly discharged to the ground through a monitoring unit with a signal lightning diode. If the earthing is not performed properly, the controllers block the process.

Road tanker earthing control system

The Earth-Rite RTR (road tanker earthing controller) system is designed to control the correct earthing of road tankers during their loading and unloading. After applying the so-called mode key, it can also be used for rail tankers, mixers, tanks, etc.

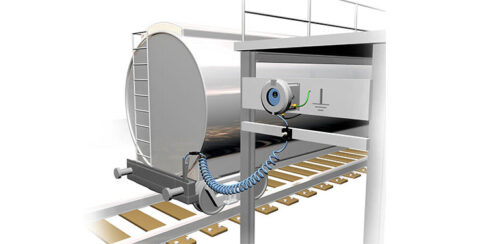

Railway tanker earthing control system

The Earth-Rite Plus type earthing control system is designed to eliminate the risk of ignition of the flammable atmosphere as a result of the jump of an electrostatic spark. The solution of this series is most often used for rail tankers and various types of containers and tanks.

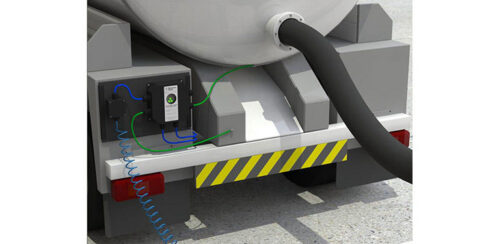

Mobile Static Earthing System

MGV is a mobile earthing control system designed for installation directly on road tankers, which are used to transport flammable and explosive substances, i.e.: liquid fuels, including liquefied gases, solvents, alcohols, fermentable materials with methane release. Its task is to reduce the risk of explosion that may occur as a result the jump of an electrostatic spark.

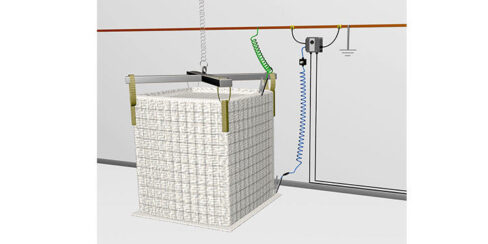

Big-Bag earthing control system

The Earth-Rite FIBC static earthing system is a revolutionary hardware system designed to ensure safe filling and emptying of type C big-bags (bags with conductive insert) used in hazardous areas.

Earthing control system for mobile and fixed plant components

The OMEGA II system allows you to include electrostatic earthing monitoring as part of larger process plant control and monitoring systems. The plant can only be started up with a resistance of less than 16 Ω, otherwise the system will not allow the plant to be started. The system can be programmed between from 2 to 600 Ω.

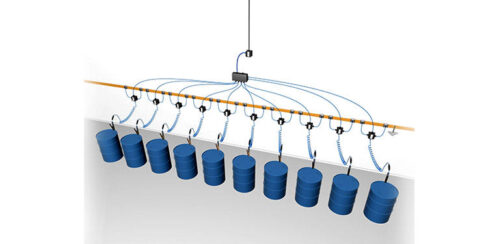

Earth control systems with process lockout for multiple devices

Multiple elements earthing control system

The MULTIPOINT II system is a device designed to control the earthing of up to 8 self-acting or interconnected system components at the same time. According to the guidelines of international standards for the control of unwanted static discharges, the correctness of earthing will only be confirmed by the system if the resistance of the earthing node on each channel is less than 10 Ω. If this condition is not met, the system will block the technological process.

Clamps with earthing control (IBC tanks, drums, big-bags)

Below is a list of dedicated technical solutions of Bond-Rite series for monitoring the state of earthing of barrels, tanks, etc. These solutions, in addition to earthing the equipment operating in production rooms, by means of a monitoring unit with a signalling diode, easily and safely verify that the charges accumulated on the equipment are properly discharged to earth. If the earthing is not performed properly, the controllers block the process.

Battery-powered system for controlling earthing of barrels, tanks, etc.

Bond-Rite REMOTE is a 9-volt lithium-magnesium battery-powered system (6 months of operation at 6 hours per day). This system should be used in situations where it is not foreseen to connect the self-testing clamps to the plant components for more than 6 hours. In case of prolonged operation, another earthing control system should be used, e.g. mains-powered Bond-Rite.

Mains-powered system for controlling earthing of barrels, tanks, etc.

The mains-powered Bond-Rite REMOTE EP has a universal ER power supply in a GRP housing and an optional junction box that allows power distribution of up to 10 Bond-Rite units. The use of this system is recommended in situations where continuous earthing monitoring is required, e.g. in the case of a barrel warehouse, where the product is regularly taken from them.

Self-testing clamps for barrels, tanks

Bond-Rite CLAMP is a earthing control system mounted on a wall or other surface. It consists of a self-testing clamp with a 3 to 15 m long spiral cable and a junction box with a pin for hanging up the clamp.

Portable clamp set with self-testing clamp

The Bond-Rite EZ is an easy to use, portable set of clamps with a self-testing clamp, which quickly and safely verifies the equalisation and earthing connections, e.g. when transferring flammable products.

Clamps, wires, spools

Earthing clamps can be used in two configurations – as a set of two simple clamps connected with each other by a spiral cable, or as a connection of the clamp to a earthed container and a ring clamp, which is located at the end of the cable, to a earthing strip.

Simple earthing clamps for single- and two-core cables

Cen-Stat earthing clamps are made of stainless steel, with sharp tungsten carbide teeth, able to break through the paint, laminate, dirt, etc.

Earthing conductors ATEX EX

Earthing conductors are characterised by a very high mechanical resistance. They have a hytrel jacket resistant to chemical and mechanical factors, which allows for their application in difficult conditions occurring in many industries.

Conductor reels

An alternative method for coiled or straight conductors is a reel for carrying away electrostatic charges. It is a very popular method ensuring a reliable connection between a ground bus and a container.

Shoe inspection stations Ex ATEX – Sole-Mate

In addition to earthing plant components, effective anti-electrostatic protection of production personnel is also extremely important. The electrified human body is one of the most serious sources that pose a fire or explosion hazard in industrial conditions. An example of a solution that checks footwear for its ability to dissipate electrostatic charges before an employee enters an area with flammable atmospheres is the Sole-Mate shoe control system.

Sole-Mate footwear control stations

Sole-Mate is a simple-to-use device intended for checking footwear or gloves for ability to carry away electrostatic electricity (anti-electrostatic properties) prior to the worker’s entering the threatened area (explosion risk atmosphere).