Dr. Andrzej Wolff has developed an innovative method for assessing the risks associated with typical equipment used for processing bulk materials. The assessment is based on the design and operating conditions of the equipment and the presence of combustible and explosive dusts.

AW-OZ: a novel approach to explosion risk assessment of equipment and process nodes used for processing bulk materials containing combustible and explosive dusts

Following many years of work in the area of explosion and process safety and the explosion risk assessments carried out for process installations in a number of industries, it was determined that there was a need to develop a new approach to risk/hazard assessment based fundamentally on process data. The objective of the work carried out was to reduce the role of subjective assessment, which characterizes the commonly used PHA (Preliminary Hazard Analysis) method. This resulted in the development of the AW-OZ methodology for quantitative hazard level assessment. It is applicable to the evaluation of typical equipment used in industry to process bulk substances that contain combustible and explosive dusts. Determining the risk value associated with the operation of the equipment allows, in the next step of the procedure, a qualitative assessment of the probability / frequency of ignition source activation and the possible consequences of an explosion using VDI approach (VDI 2263-6, 2017). The advantage of AW-OZ approach is the quantitative assessment of the level of hazard/risk associated with equipment operation and also the compliance with the provisions of ATEX User (Directive 1999/92/EC) for explosion risk assessment. Relying on reliable process data reduces the risk of taking up wrong decisions.

AW-OZ risk assessment methodology vs. the recommendations of the USERS ATEX directive

The AW-OZ quantitative hazard assessment approach for typical equipment complies with the provisions of Section 4 of ATEX User (Directive 1999/92/EC), regarding the methodology for conducting explosion risk assessments. To evaluate the level of hazard, process risk factors are used, which include the properties of the combustible dust of the bulk substances being processed, the basic elements of the equipment construction, and their operating conditions.

Thus, it is based on the following provision in Section 4 that defines the scope of the evaluation of explosion risk assessment: “the installations operated by the employer, the substances and mixtures used, the processes that take place and their interactions”.

Whereas the other provisions of the directive cover the assessment of:

- the probability and frequency of occurrence of an explosive atmosphere,

- the probability of occurrence and activation of ignition sources, including electrostatic discharges,

- the magnitude of the anticipated consequences of an explosion,

are defined in the next step of the hazard level assessment procedure. Additionally, the AW-OZ methodology offers qualitative recommendations for process and explosion protection tailored to the process equipment and the designated hazard level. Elements of this approach are presented by (Wolff et al., 2018).

Standard approaches to explosion risk assessment vs. AW-OZ hazard assessment methodology

Standard explosion risk assessment techniques emphasize the assessment of the presence of explosive atmospheres, the prevention of the ignition of explosive atmospheres, and the possible consequences of an explosion. The typical approach (RACE Project SMT4-CT97-2169, 2000) is based on hazard identification, with an assessment of risk R. This, combined with the knowledge and experience of those performing the assessment, is to ensure that hazards are identified and assigned an appropriate level of estimated risk R.

This risk is derived from the assumed values of P and S and is calculated from the equation R = P x S,

where: P is the frequency of occurrence of the danger zone / effective ignition source and S is the consequences that may occur when an explosion occurs. It should be borne in the mind that P and S are determined arbitrarily based on experience and subjective assessment of the situation. Therefore, the assessment may not always lead to correct conclusions.

Whereas, the primary purpose of the AW-OZ hazard assessment is to quantify the level of process and explosion hazards resulting from the design, presence of dust, and operating conditions of the equipment. As a result of the assessment, the level of hazard is quantified, and in the next step, solutions are qualitatively proposed to reduce the risk of ignition leading to a fire/explosion, as well as systems to protect the equipment from the effects of an explosion. The proposed quality recommendations to improve the safety of the process and explosion are tailored to the type of equipment being evaluated and the designated hazard level.

The hazard assessment does not apply to hybrid mixtures, gases, and liquid vapours. In all cases, the equipment is assumed to be properly grounded

The elements of AW-OZ risk methodology

Equipment and unit operations considered

There are no reliable and detailed statistical data collected over the years on dust explosions in the available literature. The first significant attempts at statistical coverage of explosion events (related to various industries and equipment) have been presented for last years in the annual reports of the Dust Safety Science portal (DSS Report, 2023). Based on that and the experience of the authors, a summary has been adopted that gives in % the estimated share of a typical unit operation as a place where ignition and explosion/fire can occur:

| Operation (Equipment example) | Percentage (%) |

|---|---|

| storage (silos, tanks) | 20-30 |

| dedusting (filters, cyclones) | 15-20 |

| grinding (mills) | 10-15 |

| transportation (elevators, conveyors) | 10-12 |

| drying (dryers) | 8-10 |

| mixing (mixers) | 5-8 |

| post-combustion installations | approx 5 |

The summary indicates that explosion hazards are primarily linked to storage, dust removal, and mechanical transport processes (e.g., bucket elevators), with over 50% of industrial explosions originating from these operations. Including grinding, drying, and mixing, this proportion exceeds 70%. These estimates may vary by industry and bulk material processing technology. Accordingly, the AW-OZ assessment currently considers the following bulk material processing equipment: storage silos, intermediate storage tanks, filters, cyclones, bucket elevators, screw conveyors, scraper feeders, ducts, channels, and closed transfers. For hazard assessment, this equipment is categorized into two groups:

- equipment of group R, which are characterized by a higher level of danger: storage silos, intermediate storage tanks, bucket elevators, filters,

- equipment of group RR, which are characterized by a lower level of danger: cyclones, screw conveyors, scraper feeders, channels and ducts, transfers between equipment.

Each equipment of group R or RR was assigned an individual list of process risk factors that characterize its construction and operating conditions. To assess the risks of group R equipment, the concepts of very high, high, moderate and low risk areas were introduced, and for group RR the concepts of high, moderate, low, and very low risk areas were adopted. The individual process data were assigned as risk factor values, in each of the hazard areas of group R and RR. It allows to determine the value of the summary risk of each evaluated equipment. Once the summed risk value is determined, it is assigned to one of the hazard areas of the R and RR groups, which are quantitatively defined by their upper and lower values.

Process risk factors

The AW-OZ process hazard assessment takes into account individual risk factors related to the operating conditions of the equipment. The selection of risk factors have taken into account their relevance to the operation of the equipment in question and their relatively easy availability. Possible disruptions to normal operating conditions, such as load changes, operation with changing capacity, or operational faults, are not taken into account. The summary of process risk factors for equipment groups R and RR shown on Fig.1 includes:

- Combustible properties of dust: minimum ignition energy MEZ, mJ, lower explosive limit DGW, g/m3.

- Equipment design: volume V, m3, length/height of the equipment and conveyor, ducts, transfer L, slenderness of the equipment S, diameter of the duct (channel) D, height of the filter dust removal chamber WKO, m.

- Operating conditions of the equipment:

- protection of material being transported to the equipment (magnetic separator or none) OM,

- dedusting of the equipment OA, (or none),

- movement of material into the equipment (laminar, turbulent) RM,

- type of equipment operation (intermittent operation, continuous operation) TPA,

- bearing temperature control KT (or none),

- linear speed of the screw conveyor band PLW, m/sec,

- filter operation mode (positive (fan before filter) /negative (fan behind filter) pressure) ZD,

- storage silo feed (by gravity, by rotary conveyor) RZ,

- control and extinguishing of sparks before feeding into the equipment KI (or none).

Terms related to equipment design and operating conditions were used individually depending on which factor was considered important. The selection of factors was based on process knowledge and experience in industry.

Results of equipment hazard assessment

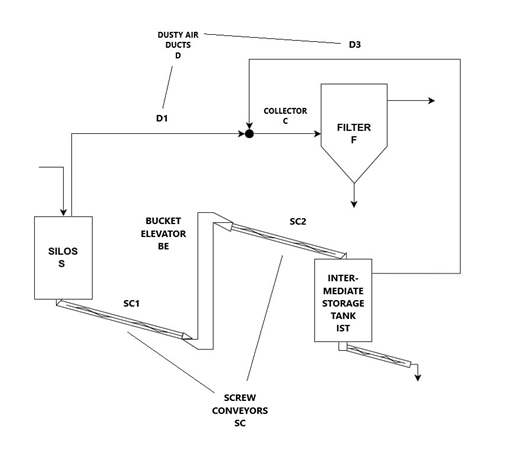

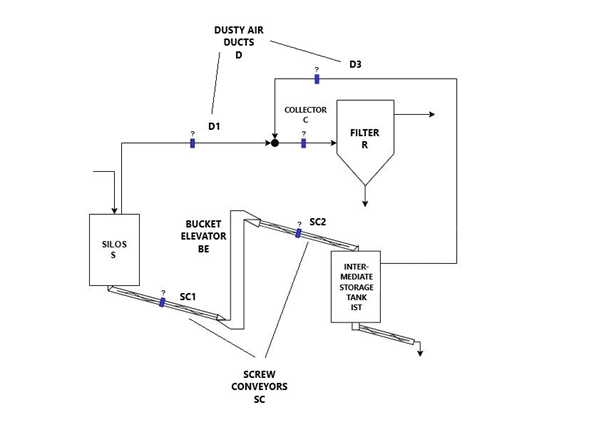

Presented below, Figure 1 includes storage silo S, intermediate storage tank PS, bucket elevator BE, filter F, two screw conveyors SC1 and SC2, dusty air ducts D1 and D3, and collector upstream of filter C2. The assessment does not include silo feed S, filter discharge F, and intermediate tank discharge PS. The plant processes bulk raw material containing dust with a low minimum ignition energy MEZ of ca. 5 mJ and a low lower explosive limit DGW of ca. 30 g/m3. As a result, material stored and transported is susceptible to potentially ignition sources. A summary of the process data (risk factors) and the designated risk levels are given in Tables 1-A and 1-B. (see the Appendix).

Equipment belonging to the higher risk group (R4, R3, R2, R1)

Applies to equipment noted as S, SC, BF and F. From the AW-OZ hazard assessment, the silo S and bucket elevator BE were classified as R4 (very high risk), and the intermediate storage tank IST and the dust collection filter F were classified as R3 (high risk). This means that these equipment, in any case, should be protected from the effects of an explosion. The preliminary recommendations obtained from the AW-OZ application (Grupa Wolff, OZ-AW, 2024) are summarized below.

The protection of silo S will depend on its location: indoor or outdoors in the production premises/buildings. In the case of an indoor installation close to a wall, it will be possible to install a relief panel with a duct that discharges the effects of the explosion into the environment, after meeting the requirements of the standard for explosion relief (EN 14491:2012). The outlet of the relief duct must be directed to a safe area away from neighboring installations, so that operators are not at risk. When this condition is not met then the appropriate solution is to use an HRD explosion suppression system (EN 14373:2021). Such a solution makes operational and explosion safety independent of the location of the equipment. Alternatively, the use of flameless explosion venting should be considered, taking into account the required restrictions (EN 16009:2011). If the silo is built outside the hall, it will be possible to build relief panels as required (EN 14491:2012). The outlet of the explosion venting must be directed to a safe area (no road or sidewalk near, close development of other equipment). When this condition is not met then the appropriate solution will be the HRD explosion suppression system or flameless explosion relief.

The protection of the intermediate tank IST will also depend on the location. In general, it can be assumed that in the vast majority of cases it will be built in the hall and not necessarily close to the wall, as its location will be determined by the course of the process line. In this case, it will not be possible to use relief panels. However, it will be possible to use flameless explosion relief or and as recommended solution HRD explosion suppression.

Following (CEN/TR 16829:2016) protection of the bucket elevator BE from the effects of an explosion will depend fundamentally on its location. In cases where the installation is located in a hallway, installing relief panels in compliance with standard conditions may not always be possible. In the case of the development of relief ducts, the outlet outside the hall area must be directed to a safe area. As a result of these restrictions, the recommended solution is to use HRD explosion suppression. This solution makes the operation and explosion safety independent of its location. An alternative is the installation of flameless explosion relief, while meeting its limitations (EN 16009:2011).

Protection of filter F (risk group R3) from the effects of an explosion will depend on its location. In the case of development in the hall, as a rule, it will not be possible to develop relief panels for the reasons stated above. The exception is the installation of the filter close to the wall of the hall and the use of a duct that discharges the effects of the explosion into safe environment. When this condition is not met, the appropriate solution will be the use of an HRD explosion suppression system. This solution makes the safety of the filter operation independent of its location. A certified rotary feeder (as explosion isolation) is recommended at filter discharge.

Equipment intakes/discharges

In addition, an issue that needs to be evaluated for the application of an explosion containment system are the intakes from silo S, bucket elevator BE, screw conveyors SC and filter F, Fig. 1. For silo S, screw conveyor SC and bucket elevator BE, the recommended application of an explosion containment system on the intakes is discussed above.

However, in the intake of filter F, it is recommended, in the first place, to use a rotary valve suitable for operation in the danger zone and with the function of a certified explosion isolation system. On the feed-in of raw material to silo S, the technical possibilities of feeding raw material are different (e.g., from a tanker truck or big bag). This element of the plant is not included in the scope of the hazard assessment. The installation evaluation stated in the chapters 4.1 to 4.3 results both from the application (risk ranking) and author’s judgment.

Using the results of the AW-OZ hazard assessment to design a customized explosion protection systems

The presented results of the equipment hazard assessment are recommendations. They do not constitute information that can be applied directly to the design of new equipment or the modernization of an operating equipment that ensures proper explosion safety. These recommendations should be the subject of consultation with a specialized company engaged in the design, installation, and commissioning of dedicated explosion protection systems in accordance with accepted industry standards.

Proposing process and explosion protection systems in accordance with the provisions of the ATEX 137 and especially of ATEX 114 directives (Directive 1999/92/EC, Directive 2014/34/EU) requires having dimensioned drawing of the equipment plan (including ducts) and cross section equipment drawings. An important prerequisites for the design of a correct explosion protection system are, moreover, the values of the parameters of dust explosibility (Kst and Pmax) and the structural strength of the equipment to the impact of reduced explosion pressure Pred,max.

In the case of a newly designed installation, such documentation and data should typically be available as standard during the detailed technical design stage. However, for an already operational plant, this information is often partially or entirely unavailable. Even when sufficient technical information is available, additional problems often arise. For example, whether it is feasible to install an appropriate isolation system that meets the technical requirements based on applicable standards. And what if it is not? The answer is neither simple nor straightforward. However, utilizing quantitative hazard evaluation through the AW-OZ approach at an early enough stage of design can help mitigate these challenges, at least to some extent

Conclusions and further plans

The AW-OZ approach enables a quantitative assessment of hazards and risks associated with equipment operating in environments containing combustible and explosive dust. The methodology complies with the ATEX User Directive (1999/92/EC) for explosion risk assessments. The assessment method is user-friendly, requiring only major process data that are easy to obtain. It supports independent evaluations for both operational and newly designed process equipment. The results provide quantitative hazard levels and descriptive recommendations for improving process and explosion safety, forming a basis for consulting specialists on process and explosion protection measures.

The OZ-AW calculation tool facilitates real-time hazard assessments using actual process data, whether during on-site audits or technical meetings for planned or existing process plants (Internet access required). This approach allows to prioritize risks and allocates resources, including financial ones, to the highest-risk areas. The AW-OZ calculation tool is compatible with PC/MAC/Linux and Android/iOS devices (Grupa Wolff, OZ-AW, 2024).

Future plans include expanding the AW-OZ methodology to assess hazards for unit operations such as grinding and mixing. This effort is complex due to the variety of technical solutions for these processes. However, detailed calculation sheets under development will extend AW-OZ’s applicability to majority process equipment.

Additionally, a new methodology is being developed for analysing hazards at the conceptual stage of technological installations. This will help determine preliminary conveying equipment lengths and ensure compliance with explosion isolation requirements. By collaborating with technologists, the methodology aims to provide clear guidelines for designing, at early stages, safer process installations for bulk processing.

The AW-OZ online risk assessment application is available for use on both mobile devices and computers.

It is aimed at the following target groups, among others:

- insurers,

- design companies,

- companies implementing turnkey process nodes and industrial installations (on commission),

- companies that manufacture market products based on organic bulk solids in their plants.

This includes the food, pharmaceutical, wood, chemical, energy, and other industries.

The main advantage of our approach to explosion risk (hazard) assessment is that, based on easily obtainable and basic process data, we obtain a quantitative assessment of the level of risk associated with the operation of process equipment/nodes and qualitative recommendations for protecting the equipment against the risk of ignition leading to an explosion/fire.

The results of the analysis presented in the Application cannot be used directly by the customer to select or purchase equipment to protect against the effects of a possible explosion. Before selection and purchase, these results should be consulted with a GW specialist in the field of process and explosion safety. GW is not responsible for the consequences of decisions made by the customer based on the results obtained while using the Application, without consulting GW and without entering into/continuing cooperation with GW on separately agreed terms.

References:

- CEN/TR 16829:2016, Fire and explosion prevention and protection for bucket elevators. European Committee for Standardization (CEN), 2016.

- Dust Safety Science, Combustible Dust Incident Report 2023. DustSafetyScience.com, 2023.

- European Parliament and Council, Directive 1999/92/EC of the European Parliament and of the Council on minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres. Official Journal of the European Union, 1999.

- European Parliament and Council, Directive 2014/34/EU on the harmonization of the laws of the Member States relating to equipment and protective systems intended for use in potentially explosive atmospheres. Official Journal of the European Union, 2014.

- Grupa Wolff, “Method of Explosion Hazard Assessment (OZ-AW).” Accessed November 2024: https://www.grupa-wolff.eu/metoda-oceny-zagrozen-wybuchem-oz-aw. [Explosion hazard assessment]

- EN 14373:2021, Explosion suppression systems. European Committee for Standardization (CEN), 2021.

- EN 14491:2012, Dust explosion venting protective systems. European Committee for Standardization (CEN), 2012.

- EN 15089:2010, Explosion isolation systems. European Committee for Standardization (CEN), 2010.

- EN 16009:2011, Flameless explosion venting devices. European Committee for Standardization (CEN), 2011.

- The RASE Project, Explosive Atmosphere: Risk Assessment of Unit Operations and Equipment. EU Project No: SMT4-CT97-2169, March 2000.

- VDI 2263-6:2017, Hazard assessment – Protective measures. Verein Deutscher Ingenieure (VDI), August 2017.

- Wolff, A., Wolff, B., & Wolff, Z., “A new approach to the assessment of explosion risk of dusts,” Chemical Engineering Transactions, vol. 67, 2018.

| Process risk factors/ Equipment | V (m3) | S | WKO (m) | OM | OA | RM | TPA | TPF | RZ | KI | KT | RISK |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Storage silo S | 50 | 6 | - | none | none | turb. | periodic | - | gray | none | - | R4 |

| Storage tank ITS | 10 | 6 | - | none | none | lam. | cont. | - | gray | none | - | R3 |

| Dedusting filter F | 6 | - | 4 | - | - | - | cont. | under | - | none | - | R3 |

| Bucket elevator BE | 5 | 35 | - | none | none | - | cont. | - | - | - | none | R4 |

Table 2A: Summary of data and results of the hazard assessment for higher-risk equipment. MEZ = 5 mJ, DGW = 30 g/m3, grav. is ‘gravity feeder’, turb is ‘turbulent flow’, lam is ’laminar flow’, cont. is ‘continuous’.

| Process risk factors/ Equipment | V (m3) | L (m) | D (m) | OM | TPA | KT | PLW m/sec | ZO | ZD | KI | RISK |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Screw conveyor SC1/SC2 | 2 | 5 | - | - | cont. | none | 2 | - | - | - | RR3 |

| Collector C2 | - | 5.5 | 0.45 | none | cont. | - | - | none | - | none | RR3 |

| Duct D3 | - | 10 | 0.4 | none | cont. | - | - | none | - | none | RR3 |

| Duct D1 | - | 8 | 0.45 | none | cont. | - | - | none | - | none | RR3 |

Table 2B: Summary of data and results of the hazard assessment for lower-risk equipment. MEZ = 5 mJ, DGW = 30 g/m3, cont. is ‘continuous’.