Line temperature sensor | fire detection system

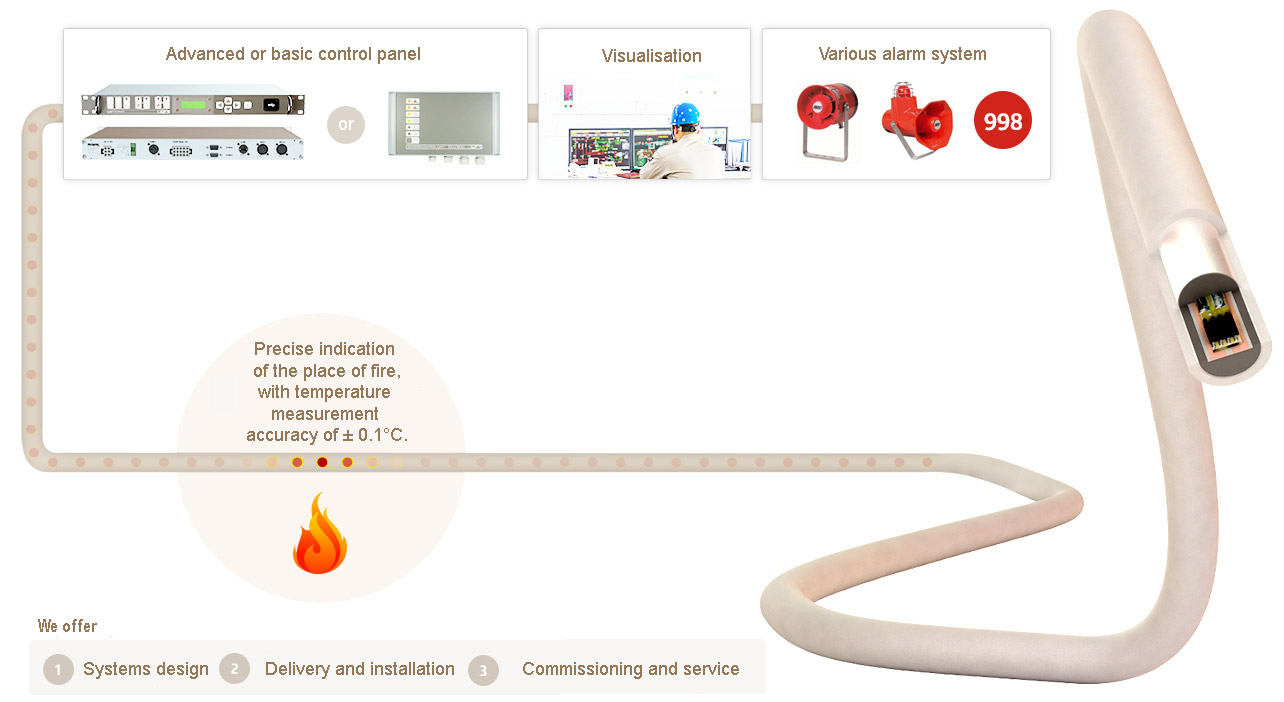

We design and implement complete fire detection and alarm systems based on a line temperature detector (or other detectors selected adequately to the working conditions), which is a special active cable with embedded sensors. The solution is intended to be applied in hardly accessible spaces or when temperature measurement is required along long sections reaching from several dozens to several thousands meters. Typically line temperature sensors are applied in detecting belt conveyor failures or fires, cable routes overheating, detecting fires in transformer rooms, tanks, tankers and pipelines temperature monitoring. The line temperature sensor precisely indicates the source of fire or overheating of the monitored equipment or cable route.

The system does not require calibration but still works with very high accuracy (± 0.1°C). Moreover temperature detector compliant with the Standard EN 54-22 (line-type heat detectors as an element of fire alarm systems). It is important that the system may be used in hazard explosion zones.

What we will do for you

Depending on customer needs, we implement all or only selected tasks presented below. You are viewing a site devoted to a fire detection system based on line detectors, which means active cables which measure temperature along their length. This solution is ideal when temperature needs to be measured in many points at the same time at the distance of several dozen meters or even dozens of kilometres (belt conveyors, cable ducts, tunnels, pipelines, etc.). Our fire detection systems may also be based on other types of detectors so that they fit the specific needs of an industrial system, warehouse, garage or a sacral building.

FIRE-FIGHTING DOCUMENTS

The current regulations require that a fire safety plan and fire scenarios for the premises subject to fire hazard are prepared. They are basis for further works consisting in designing and implementing the fire alarm systems or complete fire-fighting systems. If no such documents have been prepared for the respective structures, we may start from preparing them..

- Fire safety plan – the document is required for buildings and their parts representing separate fire zones, intended for performing public utility functions, boarding house, production building, warehouse, livestock building, where hazard explosion zone is present, or:

- the gross cubic volume of the building or its part representing a separate fire zone exceeds 1,000 m3 (does not apply to livestock buildings),

- the gross cubic volume of a livestock building exceeds 1,500 m3,

- the fire zone area of a structure other than a building exceeds 1,000 m2.

- Fire scenarios – a fire scenario is a description of the sequence of the possible events during a fire, representative for the respective place of its occurrence or area of impact, specifically for a fire zone or a smoke zone, considering mainly the way of operation of fire-fighting equipment, utility or engineering equipment, as well as their joint operation and interaction, and also organisational solutions needed for the proper operation of the designed safety measures..

- ATEX documents – apart from the aforesaid documents, mainly in reference to industrial structure, our documentation department also prepares such documents as:

Explosion Hazard Zones Setting

- Explosion Hazard Assessment

- Explosion Risk Assessment

- Explosion Protection Document

FIRE DETECTION SYSTEM DESIGN

We design fire detection systems in consideration of the working conditions, specific requirements of the given building and fire scenarios provisions. Completely different requirements apply to a system protecting belt conveyors in a coal conveyor gallery, and different to a historic building or a church. A coal conveyor gallery is characterised with high-dustiness, humidity and variable temperatures, whereas in a sacral building it is important to install the system without any major interference in the building integrity. Each of the structures is, therefore, characterised with different requirements and working conditions which need to be planned at the designed stage.

Therefore, design work is preceded with an audit and interview, which indicated serious problems and assumptions for further work consisting in implementing an effective fire detection system.

.

Selected components applied in the designed fire detection systems:

- Fire alarm panel

- Emergency power supply equipment

- Manual call points

- Optical smoke detectors

- Line heat detectors

- IR flame detectors

- Supervising module

- Signal controllers

- Status indicators

- Strobe light sirens

- Integrating and non-visualisation software

FIRE DETECTION SYSTEM INTEGRATION WITH OTHER SYSTEMS

When implementing a fire detection system, we integrate it with various safety and building automation systems. We also create visualisation, which we combine with the building or industrial system layout plans. This enables implementation of the assumed fire scenarios and managing the whole safety system in an efficient and intuitive manner.

The systems we integrate:

- explosion protection system (unique integration on the market)

- access control system

- voice alarm system

- fire lockout system

- fire dampers system

- lift system

- ventilation system

DELIVERY, INSTALLATION AND COMMISSIONING OF A FIRE DETECTION SYSTEM

With our installation group we are capable to perform a task in a comprehensive manner, i.e. starting from preparing fire scenarios, through concept and design, and ending with delivery and installation. In this way our customer may rely on a partner responsible for all of the implementation stages. Such solution may significantly facilitate the investment process, providing a guarantee that the final effect complies not only with the legal requirements but also the customer’s individual expectations.

Application of line temperature detectors

Fire detection and alarm as well as temperature monitoring for industrial equipment.

POWER ENGINEERING

- Detection of overheated rollers/belts in belt conveyors

- Detection of overheating in cable tunnels/ducts, for heavy-duty cables

- Detection of fire in transformer rooms

- Monitoring of cables in raised access floors in electric switch rooms

CHEMICAL AND PETROCHEMICAL INDUSTRY

- Detection of fire in dangerous places

- Temperature measurements along pipelines

- Temperature monitoring in tanks and tankers

ENCLOSED STRUCTURES

- Detection of fire in underground garages

- Detection of overheating in cable tunnels/ducts

- Monitoring of cables in floors and suspended ceilings

- Monitoring of temperature in hardly accessible places

MINING

- Detection of belt conveyor damage

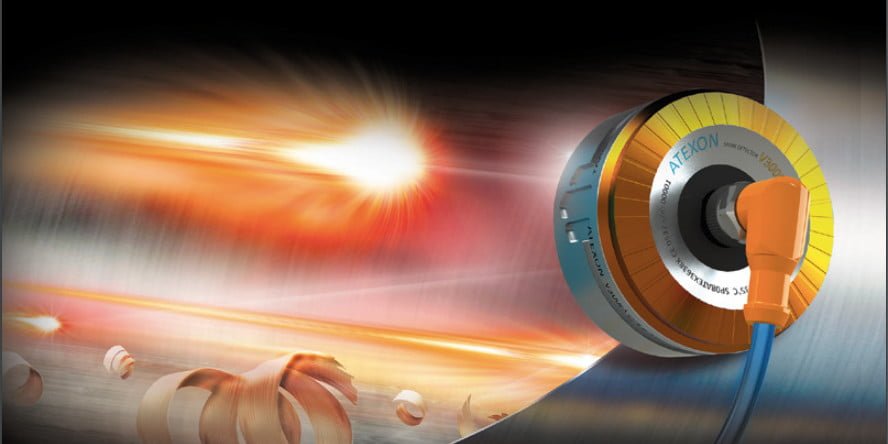

- Detection of overheating in cutting machines

- Detection of overheated rollers/belts in belt conveyors

Concept of a fire detection and alarm system based on a line temperature detector

The line temperature detectors applied in our solution enable specific determination which zone, or even which section or point within the zone has been heated. The settings and sensitivity parameters of line detectors comply with the EN 54-5 standard (A1 class of point temperature detectors). The principle of the detector operation, which has been confirmed by test reports for all line detectors, is simple and consists in signalling the occurrence of:

- a value of excessive temperature,

- a slight temperature differential,

- a slight temperature differential referred to the system temperature profile or its modification based on the manufacturer’s algorithms.

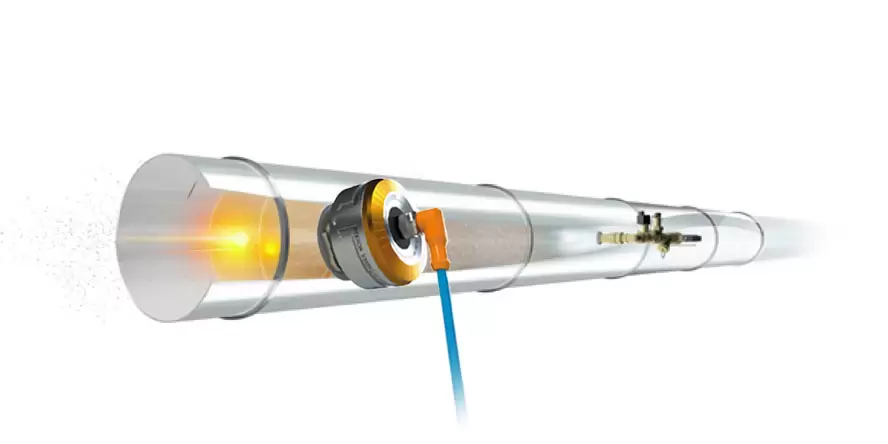

Line temperature sensor – active cable

The applied active cables are resistant to vibrations, electromagnetic field interference, humidity and other environmental factors. The sensor embedded therein are addressable, which helps detecting a fire/failure with the accuracy to the specific point. The sheath of the cable does not contain halogens, which guarantees safety and absence of toxic halides emission during the evacuation of people from the hazardous building, whereas an aluminium screen protects the cable against electromagnetic interference.

An active cable does not require any service during operation. The cable may be as long as 3,200 m. It may be branched or connected to external detectors.

HIGH RANGE – thanks to the applied engineering solution a single active cable may be as long as 3,200 metres.

EXACT MEASUREMENT – an active cable ensures high measurement accuracy (± 0.1°C) along the whole length of the cable.

HIGH FLEXIBILITY – the cable structure provides it with high flexibility which means that it is easy to lay it to the required shape.

BRANCHING POSSIBILITY – an active cable may be branched, and external temperature detectors may be added to it.

WITHOUT CALIBRATION – the system does not require any calibration either before or during operation.

PRECISE FIRE/FAILURE LOCATION – the system precisely indicates the source of fire (for example, the distribution of sensors in the cable every one metres makes it possible to detect a fire with an accuracy to one metre).

COMPLIANCE WITH STANDARD EN 54-22 – it is the line-type detectors as an element of fire alarm systems.

Line temperature detector controller – fire detection

In our systems we apply a state-of-the-art controller to manage the line heat detectors. It has inbuilt Ethernet and RS485 interfaces as well as a series of communication protocols, e.g. MODBUS.

The controller may use up to 254 alarm transmitters. Moreover, it has a robust ARM9 processor and an LCD display with background light changing colour depending on the system status. That simple solution clearly signals the normal operation of the system, an alarm, a fault or redundant operation (RDT). Thanks to a convenient www interface in Polish programming and servicing is extremely easy and intuitive. The controller is capable of monitoring an active cable of the length up to 3,200 m and/or 350 sensors.

Advanced line temperature detector controller

In this section we are going to present a state-of-the-art device which is present on the market of line heat detectors. Its basic parameters include:

- a definition and measurement accuracy of ± 0.1°C along the whole length of the active cable

- every 10 seconds measurement cycle

- 254 individual programmable zones

- two inputs for active cables

- IP65 protection class

- compliance with the PN-EN 54-24 standard (line-type detectors as an element of fire alarm systems)

- possibility to cooperate with an active cable, external temperature detectors and a remote RDU 316 display (see below)

possibility to ensure a redundant mode of operation - no false alarm generated by external temperature fluctuations

- a robust ARM9 processor

- possibility to apply various access passwords with differing levels of access

- configuration in many languages

A simple line temperature detector controller

The controller is an optimal solution with regard to engineering and price for most of the tasks. Its basic parameters include:

- a definition and measurement accuracy of ± 0.1°C along the whole length of the active cable

- every 10 seconds measurement cycle

- 16 individual programmable zones

- two inputs for active cables

- IP65 protection class

- compliance with the PN-EN 54-24 standard (line-type detectors as an element of fire alarm systems)

- possibility to cooperate with an active cable, external temperature detectors and a remote RDU 316 display (see below).

A remote display to work with the controllers

A display is useful in receiving the most important information on the system status from the distance of even 1,000 metres. The device receives the date from the temperature detector controller. It basic parameters include:

- possibility to read a message from the line temperature detector controller through the RS485 interface from the distance of up to 1,000 m

- alarm or fault message

- USB interface to update software

- membrane keyboard with five buttons to navigate the menu

- an LCD display with different colour backlight depending on the state of the system