Comprehensive fire protection for power stations and combined heat and power plants.

We design and supply fire protection systems for power plants and combined heat and power plants – whether they are the largest or smaller plants, or decentralised power plants producing energy and/or heat from coal or biomass for their own production purposes (such as cement plants). Often our projects for the energy industry involve ensuring both fire and explosion safety.

Click and see what we do:

- Comprehensive protection of a sloping bridge: fire detection and alarm system and sprinkler system

- Internal hydrant systems

- Fire water pumping station and fire water tank

- Extinguishing transformers

- Oil tank extinguishing systems

- Upgrades of lighting (primary, evacuation, emergency) to meet the fire requirements

- Smoke extraction in stairwells and other upgrades

Practice based on the experience in…

…the protection of biomass and coal combustion installations against fire and explosion hazards. The list opposite shows the companies for which we have designed and built protection systems and have largely carried out explosion risk assessment studies.

We specialize in

Industrial facilities

Industrial facilities

- energetics

- wood industry

- food industry

- waste processing

- chemicals and petrochemicals

Fire safety guidelines and standards

- PN-EN

- VdS

- FM Global

- NFPA

Corrosive environment

- we select plant components to suit your operating environment

- experience in “difficult” industries,

- including C5M/C5-I corrosive environments

Zdajemy sobie sprawę, że większość inwestycji związanych z modernizacją instalacji przeciwpożarowej wynika z wymogów, które stawiają zakładom przemysłowym ubezpieczyciele. Jeśli też jesteś w tej sytuacji, zapewne ubezpieczyciel wskazał, zgodnie z jaką normą lub standardem mają być wykonane zabezpieczenia przeciwpożarowe. Najważniejsze dla Ciebie jest to, że niezależnie jakie wymagania nakreślił Tobie ubezpieczyciel, spełnimy je wszystkie.

Which areas of the power plant do we protect?

A FIRE AT A POWER STATION MEANS LOSSES OF MILLIONS OF

We have already carried out work on a number of power stations and combined heat and power plants. We have seen the damages from a possible fire, or explosion, in such facilities. The vast majority of the demand for energy and system heat in Poland is met by burning coal and cogeneration with biomass. These types of facilities are designed for continuous operation, so a possible fire could result in millions of zlotys in losses, but also huge problems in ensuring the continuous supply of energy and heat to consumers.

WHAT DOES OUR WORK FOR THE ENERGY INDUSTRY LOOK LIKE IN PRACTICE?

For power plants and combined heat and power plants burning coal (or coal with biomass), we have to take into account many factors that make up an extremely harsh working environment. First of all, there is the high temperature and high level of dust. As a result, any fire safety project must eliminate not only the risk of fire, but also the risk of a false fire alarm. This switching on of the fire fighting system as a result of a false alarm can also lead to millions of zlotys in damage.

WHAT WE ARE PROVIDING

Installing detection systems capable of detecting smouldering fires

Selecting detection and signalling systems to withstand harsh working conditions

Preventing false alarms, i.e. put out only when there is a fire

Minimising losses resulting from triggering an extinguisher due to a false alarm

Protecting all key facilities at thermal power plants / power stations

Carrying out the work without affecting the continuity of operations of the power plant

We move and work only in the areas which were made available to us

We strictly adhere to all safety procedures

Remember that coal dust, like biomass dust, is explosive!.

Therefore, in addition to ensuring fire safety, explosion safety must also be ensured in many areas of the power plant / CHP plant in accordance with the provisions of the ATEX Directive.

Scope of fire protection systems we implement

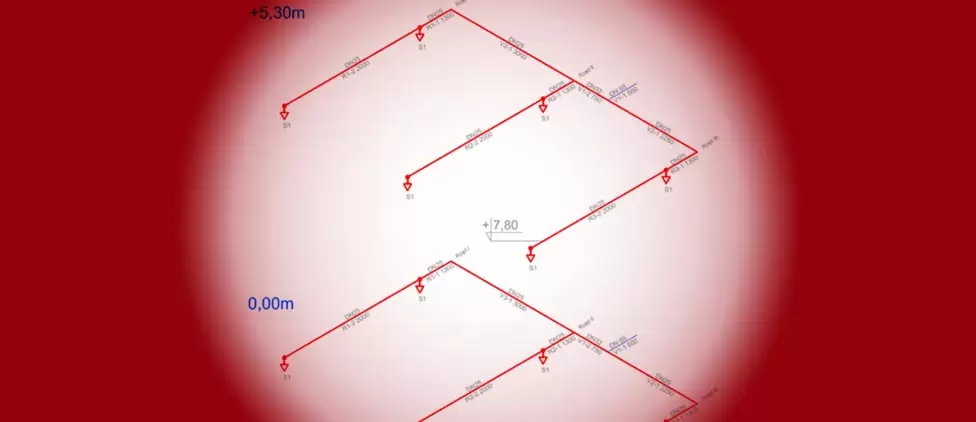

PROTECTION OF THE ANGLED BRIDGE

We divide the bridge into multiple sprinkler sections so that the entire length of the conveyor is not flooded in the event of a fire

We make the installation, the piping, the sprinklers and feed the water to them and provide control panels

If required, we supply pipeline heating systems to prevent water from freezing

When designing a fire alarm system, we take into account the extremely difficult operating conditions for the sensors in order to counteract false alarms

We ensure that a fire can be detected quickly even at the smouldering stage

We supply optical and acoustic signalling devices

INTERNAL HYDRANT SYSTEM

We design and install internal hydrant systems and upgrade the existing hydrant systems

We connect hydrant risers to increase the pressure in the system and provide the required capacity

We carry out our the tasks without disturbing the facility

FIRE WATER PUMPING STATIONS AND RESERVOIRS

We design and install fire water pumping stations and fire water tanks – even with a capacity of approx. 1,000 m3; we modernise existing pumping stations

We carry out the task comprehensively: from the design, delivery and assembly to the E/I&C and electrical installation work, down to the finishing work and creating documentation.

We carry out our the tasks without disturbing the facility

OIL TANK PROTECTION

We design and install sprinkler systems for oil tank protection

Depending on your needs and budget, we provide either water sprinkling (main purpose: to cool the area until the fire brigade starts fire fighting) or foam extinguishing (main purpose: to extinguish the fire)

PROTECTION OF TRANSFORMERS

We design and install sprinkler systems for oil transformers

We recommend a prefabricated self-supporting cage mounted with quick-connectors, which avoids the construction of an expensive substructure. At the same time, this cage design allows the owner, if necessary, to remove part of the ring to gain access to the transformer.

We supply control panels, trigger valves and under-station gate valves.

UPGRADING OF STAIRCASES (AND OTHER FACILITIES IN THE POWER PLANT AREA) TO FIRE SAFETY REQUIREMENTS

We supply smoke dampers with an electric smoke control system, which we connect to the extinguishing control panels

We carry out the necessary upgrades of basic, emergency and evacuation lighting

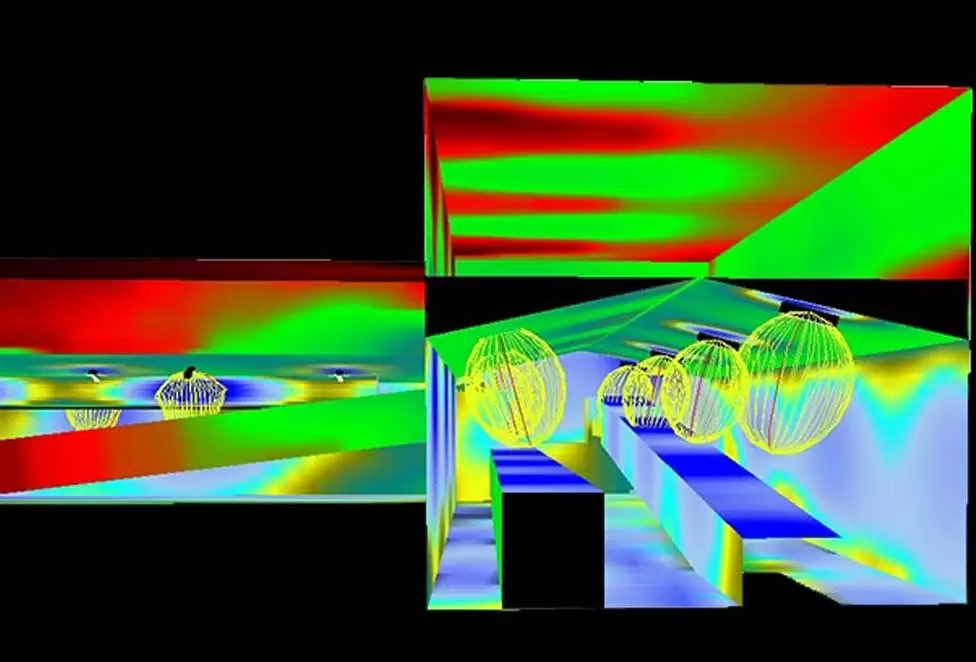

We carry out a calculation of the existing lighting with a visualisation of the deficiencies to be corrected

We also supply lighting panels, lighting connectors, junction boxes and electric shock protection systems

Fire systems – the offer

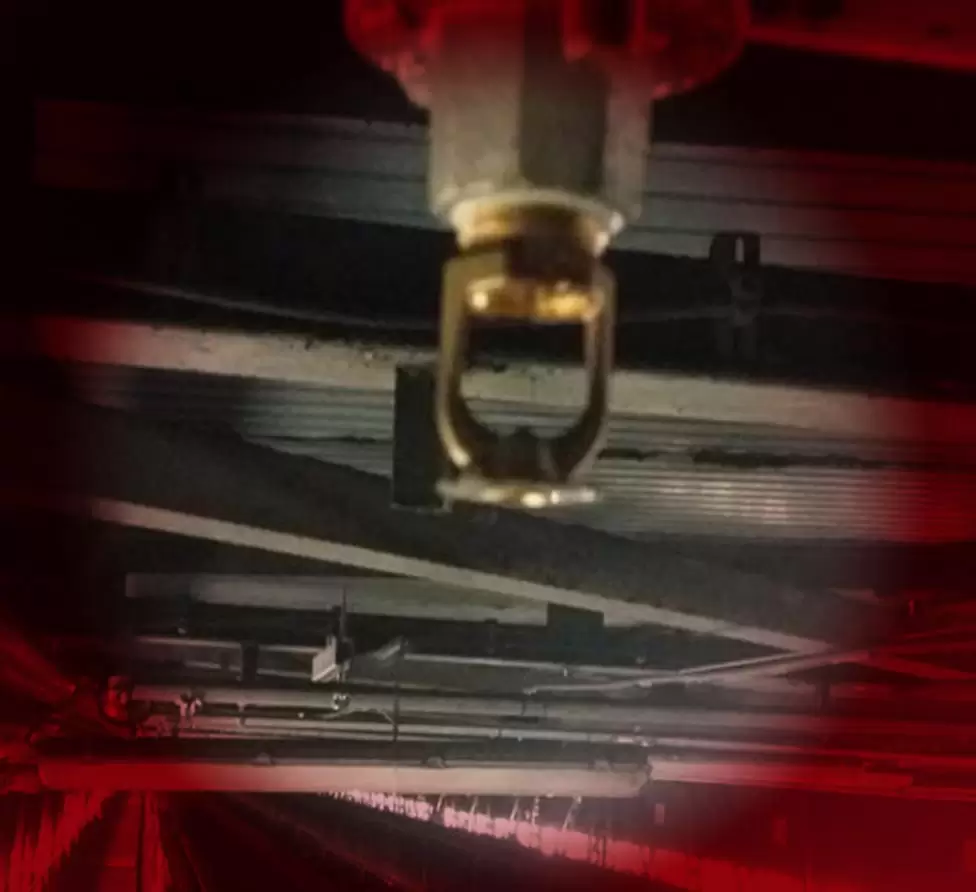

Sprinkler systems.

They are self-contained fire extinguishing systems that detect the moment a fire starts, then send information to the control system and automatically start the process of selective water extinguishing – only where there is a fire.

Deluge sprinkler systems.

They are equipped with open fire nozzles and can be divided into several extinguishing zones. When a fire is detected, the sprinkler valves for the area open. Water is released throughout the protected area.

Foam installations.

In particular, we use them for facilities with a high fire risk, such as: tanks for fuels, solvents and other flammable liquids; warehouses for plastics; warehouses for flammable products and/or locations where explosive atmosphere occurs.

Fire Detection and Signalling.

Designing and implementing comprehensive fire detection and alarm systems. Depending on your needs, we use one of the four available systems or a combination of two or three of them, to optimise your investment from a technical and cost perspective.

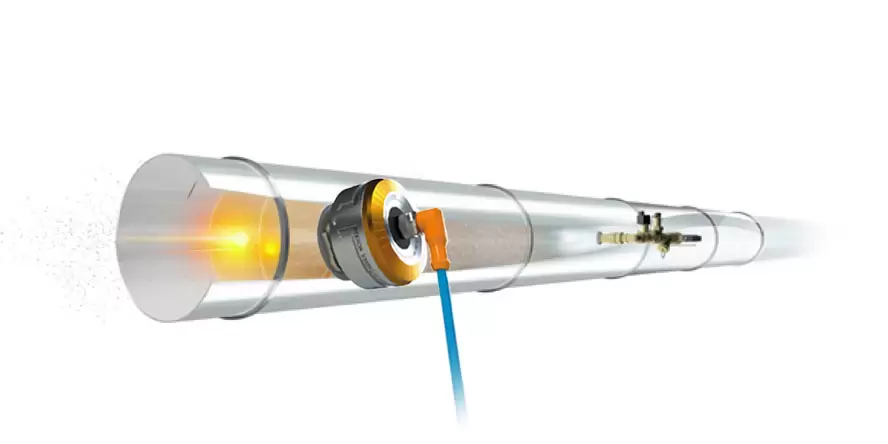

Spark Detection and Extinguishing.

These systems are designed for installation in the ducts of industrial installations. Their purpose is to prevent a potential ignition source in the form of a spark, cigarette butt or heated particle from entering the appliance.

Secure your installation.