Safety plates are intended for sanitary and aseptic applications, therefore, they are a perfect solution for pharmaceutical, biotechnological and food industries. Moreover, due to their properties, they can be successfully applied for gases, vapours and liquids.

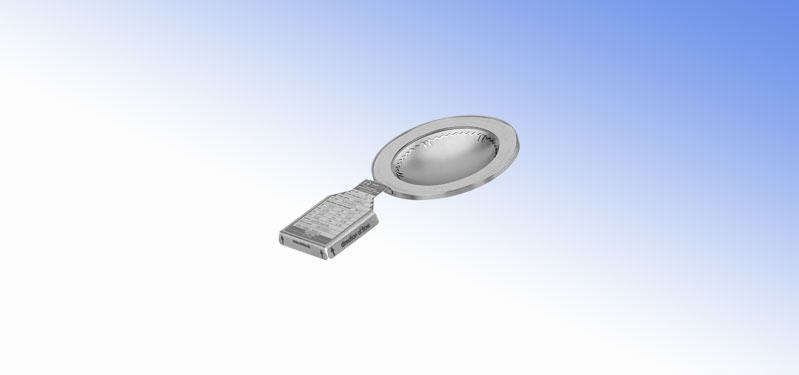

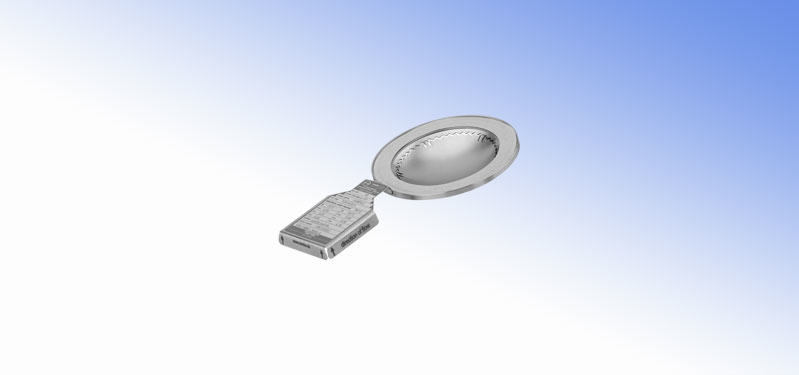

The safety plates presented have on the process side perfectly smooth, convex surfaces, without any dead spaces. Their design allows for operation with pressures reaching 98% of the bursting pressure value.

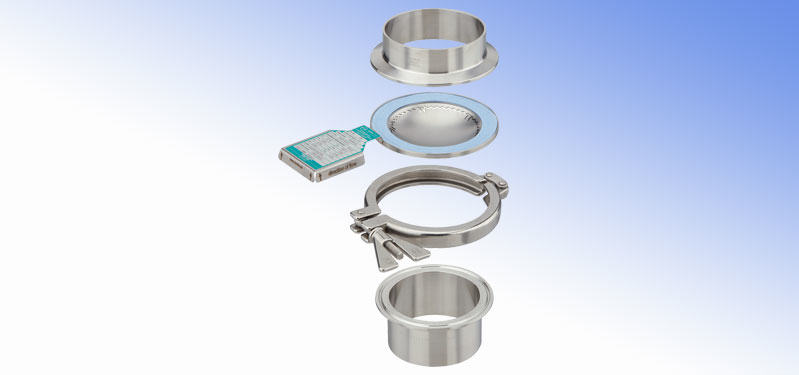

The robust construction of the plate enables its quick and easy mounting in standard type tubular connections without the necessity to verify the torque. The PTFE sealing, integrated with the plate and typical for tri-clamp type connections, can replaced in case of need, without replacing the whole plate. Optionally, the system can be equipped with a special signalling plate which indicates activation of the proper plate. The signalling plate is mounted behind the real plate and in normal conditions, it has no contact with the product. It is mounted in the same way as the proper plate.

- Minimum bursting pressure: 0.01 bar(g)

- Dimension: 20-800 mm

- Max. Admissible operating pressure: up to 98% of the bursting pressure

- Installation: between flanges in an integrated head and a tri-clamp type holder

- Construction: two-layer, with a reversed shape

- No fragmentation after action

- Very long life span

- Design resistant to corrosion

- Guarantee of a complete opening of the plate

- Smooth surface on the process side

- Suitable for pulsating pressure

- Sanitary and aseptic design

- Sealing preventing diffusion

- Liquid and gaseous media

- Complex chemical, biochemical, pharmaceutical processes

- Sanitary and aseptic applications

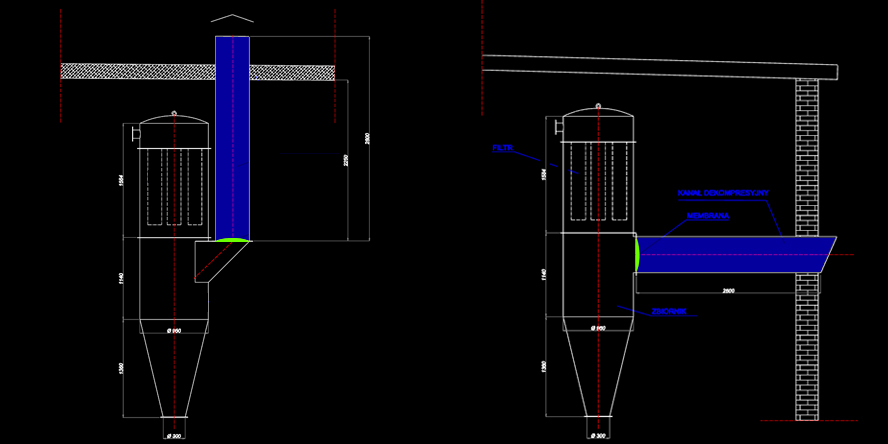

- Pressure equipment and apparatus, such as reactors, tanks, pipelines, gas cylinders, etc.

- Stainless steel

- Nickel

- Aluminium

- Inconel

- Monel

- Hastelloy

- Tantalus

- Titanium

- Making necessary calculations

- Delivery and installation