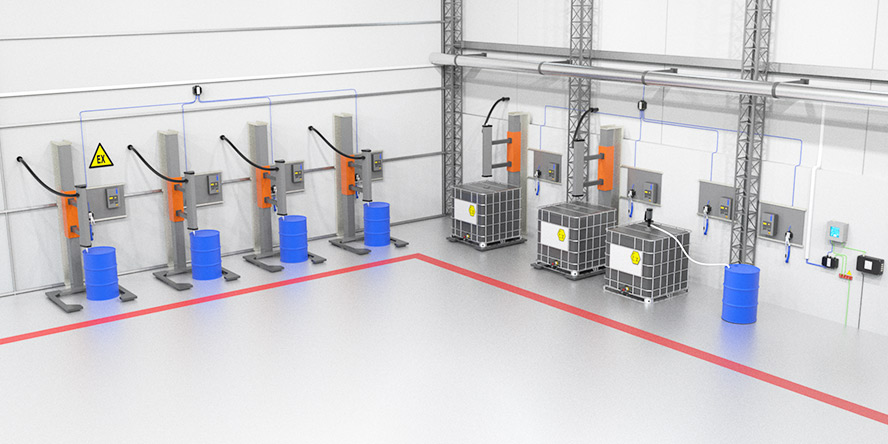

ADR tanker grounding or, more precisely, the grounding control system for road tankers, is designed to ground and monitor the correct grounding of a vehicle during filling, emptying and washing. After the application of a so-called mode key, the tanker ground tester can also be used for grounding rail tank cars, mixers, drums, IBC tanks, etc.

Intended use

- grounding and grounding control of road tankers,

- the only system certified for hydrogen,

- grounding control of tanks, drums, big-bags, etc. (only if a mode switch is used).

Grounding inspection system certificates

How to properly ground a tanker

Find out, what missing grounding of electrostatic discharge can lead to when filling/emptying or, for example, washing a tanker truck, and how to ground the vehicle correctly to prevent a similar incident. NOTE: the video includes two CCTV footage showing the ignition of an explosive atmosphere during the loading/unloading of a tanker.

Also certified for hydrogen

IMPORTANT: hydrogen is one of the most explosive substances. Our system is the only one that complies with all of the following requirements of the so-called hydrogen standard and good practice, and can therefore be used safely with hydrogen as well as other gases, vapours and dust.

- It is ATEX and IECEx-certified for gases of the so-called hydrogen group (Group IIC) – thus suitable for hydrogen and all Group IIA gases and vapours II B i IIC – hydrogen standard requirement

- verifies that the earth resistance is less than 10 ohms – a requirement of the hydrogen standard

- SIL 2 certified for high reliability

- recognises road tankers (can be deactivated when grounding other objects)

Diagram of the grounding control system for road tankers

NOTE: the system ensures both, grounding and grounding status monitoring. If there is no grounding, the system can be used to block the process.

Components and additional options

Certified grounding tester

Grounding monitoring unit in ATEX design for flammable gases (including hydrogen), liquid vapours and dust. Very robust cast aluminium housing with no copper content. The unit is equipped with a traffic light to inform the operator of the grounding status (green: correct grounding/red: no correct grounding).

Grounding monitoring unit in ATEX design for flammable gases (including hydrogen), liquid vapours and dust. Very robust cast aluminium housing with no copper content. The unit is equipped with a traffic light to inform the operator of the grounding status (green: correct grounding/red: no correct grounding).

Control of pump, valve, signalling systems

With two safety switches, it is possible to use the grounding monitoring unit to switch the pump on and off, for example, to switch the pump on and off, sound an audible signal or open/close the valve.

| ATEX |

Can be used in hazardous areas

Gases and vapours: zone 2 and 1 Dust: zone 22 and 21 |

| Power supply |

115 V or 230 VAC, 50-60 Hz

12 V lub 24 V DC |

| Working temperature | -40°C to +55°C |

| Protection rating | IP 66 |

| Weight | 4,5 kg |

| Housing |

Copper-free aluminium casting

|

| Parameters of the output contacts |

Two potential-free switches

250 VAC 5 A 500 VA max. resistive 30 VDC 2 A 60 W max. resistive |

| Cable inputs |

7 x M20 (two blanked)

|

Ground clamp

Very robust, ground clamp with high tooth force which you can easily squeeze with one hand at the same time.

Teeth made of the hardest material on earth

Tungsten carbide is one of the hardest conducting materials on earth. It is used, among other things, in anti-tank missiles due to its amazing properties. History tells us that the German military only started using it after it was discovered that it was being used by… Poles. But this is not the topic for today. It is from tungsten carbide that the teeth of our clamps are made. Why? Because tungsten carbide guarantees long-lasting clamp operation and the highest level of safety – the teeth, which remain sharp for a very long time, pierce through paint coating, laminate, dirt or rust with ease. And only then are we able to guarantee a secure and permanent grounding.

Tested durability

The durability of the tungsten carbide teeth has been proven by our test (see video) – it turned out that even a very hard blow with a hammer on a sharpened tooth did not leave any marks on it. For comparison, we performed a second test using a tooth made of steel – we found that the same impact completely destroyed it. The initially sharp tooth of steel has turned into a completely flat bar. The tip of the tooth formed a flat surface approximately 3 mm in diameter.

And what if the teeth become blunt

The teeth in our clamps are incredibly hard. But let’s make it clear, nothing lasts forever. Even tungsten carbide will wear out at some point. What should we do then? Do you have to replace the entire clamp? Absolutely not. Forcing you to do so would not be fair. That is why the teeth in our clamps are interchangeable. Simply unscrew the two screws and replace the teeth with new ones in a matter of minutes. This is a cost-effective and quick solution which means that the bracket can work between a couple and several years.

Ground clamp with spiral cable

Exceptional Durability

The cable is the most critical element of the grounding system. Constant friction against the ground, sharp edges of the tank, contact with chemical substances, fuel, and lubricants, as well as the risk of being run over by a vehicle, mean that it must stand out with exceptional durability. To maximize its lifespan, we use cables insulated with the Hytrel® elastomer from DuPont™. This material is used, among other things, for the production of protective covers for drive shaft joints in cars, which must withstand constant impacts, tugs, and bending in various weather conditions. This guarantees very high resistance of our cables to chemical and mechanical factors.

Very Quick Replacement

But that’s not all. The cable connects to the grounding clamp and the grounding monitoring unit through two safe quick connectors. This allows for its very quick replacement in just a few dozen seconds.

Constant Cable Damage Monitoring

It happens that electrical cables are damaged in ways invisible to the eye. In the case of a grounding cable, this would mean a lack of grounding for the tank. The operator would continue to use the grounding, unaware that it is completely ineffective. To avoid such a situation, the monitoring unit continuously verifies the condition of the cable. This is one of the three stages of verifying the grounding condition.

Key Features of Spiral Grounding Cables

| Protection against damage |

Encased in insulation made of the exceptionally resistant to mechanical and chemical factors elastomer brand Hytrel® by DuPont™

|

| Cable damage monitoring | Yes, continuously through the monitoring unit |

| Number of cores | 2 x 1.00 mm² – copper |

| Available lengths | 5, 10, 15 m (when stretched) |

| Quick replacement | Yes, through two safe quick connectors |

| Available colors | Blue (standard), green, red |

Additional options

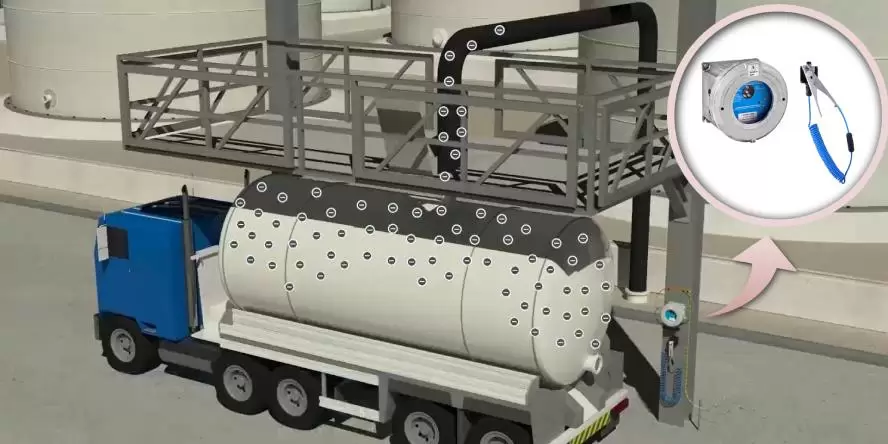

Reel instead of a spiral cable

Reel instead of a spiral cable

The self-retracting reel is a great alternative to spiral cables, which are provided with the system as standard. The reel will extend the lifespan of the grounding cable and ensure even more convenient use of the system. The reel comes with cables of any length not exceeding 15 m. The cable has a cover made of Hytrel, resistant to mechanical and chemical factors. The reel has an ATEX certificate for gas zones (1, 2) and dust zones (21, 22).

Breakaway connector

Breakaway connector

According to the procedure, the grounding system should be disconnected from the tank after completing all activities related to the loading/unloading process or cleaning. It happens that the driver forgets to remove the clamp from the vehicle before departure. This risks damaging the controller. To prevent this, we suggest placing a special connector right after the grounding clamp, which will disconnect during a strong tug, protecting the grounding control system from damage.

System operation correctness tester

The tester simulates the electrical parameters of truck tanks to verify if the grounding control system is functioning correctly. After connecting and activating the tester, a properly working grounding control system should display a green light. The tool allows for periodic tests to ensure the highest level of safety.

Indicators

To enhance safety levels, it is possible to provide the grounding control system along with acoustic, optical, or combined acoustic-optical indicators. Indicators are available for both explosion hazard zones and non-hazardous areas, for operation in challenging conditions as well as indoors.

Principle of the ground tester

Earth Rite RTR is an advanced system, designed to monitor the correct grounding status of road tankers during filling, emptying, washing and other processes that generate explosion risks. The grounding tester provides a three-stage verification of the correctness of the tanker’s grounding, which we have shown both in the video and below.

What verifies the grounding control system of the road tankers:

Has the clamp been correctly attached to the tanker? – The processes of filling or emptying the tanker will only be possible in cases when

-

- the ground clamp has been connected to the road tanker, and not to another structure or metal object,

- the ground clamp has been connected to the vehicle component, which allows static electricity to be dissipated from the tank container (avoids the mistake of attaching the clamp to a non-conductive or isolated component, such as a gasket or varnish).

Grounding verification – the grounding tester checks that the connection to the hoop iron is correct, so that charges can be discharged unhindered to earth.

Connection to the ground – in case of loss of connection (loosening of the clamp, damage to the lines, etc.) the filling/emptying process of the tanker will be blocked.

Destructive tests

What happens, if we hit the needle-sharp tooth of the ground clamp with all our might with a hammer?

Important

A truck tank, with an average electrical capacity of 5000 pF, can cause an electrostatic discharge with energy reaching up to 2250 mJ. This is several dozen to several thousand times more than the minimum ignition energy of gases, vapors of flammable liquids, and dust. For example, the minimum ignition energy of vapors and gases rarely exceeds 1 mJ, while for dust, it most often oscillates around several dozen mJ.

2250 mJ – this is the energy a spark from a tanker can achieve

Minimum ignition energy of vapours and gases

| Explosive atmosphere | Minimum ignition energy [mJ] |

| Propanol | 0,65 |

| Ethyl acetate | 0,46 |

| Methane | 0,28 |

| Hexane | 0,24 |

| Methaneol | 0,14 |

| Carbon disulphide | 0,01 |

Minimum ignition energy of dust

| Dust cloud | Minimum ignition energy [mJ] |

| Wheat flour | 50 |

| Sugar | 30 |

| Aluminium | 10 |

| Epoxy Resin | 9 |

| Zircon | 5 |

| Certain pharmaceutical intermediates | 1 |