Newson Gale Earth-Rite MGV

MGV is a mobile earthing control system designed for installation directly on road tankers, which are used to transport flammable and explosive substances, i.e.: liquid fuels, including liquefied gases, solvents, alcohols, fermentable materials with methane release. Its task is to reduce the risk of explosion that may occur as a result the jump of an electrostatic spark.

This solution therefore increases the security of the process and allows to fulfil the obligations arising from the relevant regulations of the Minister of Economy.

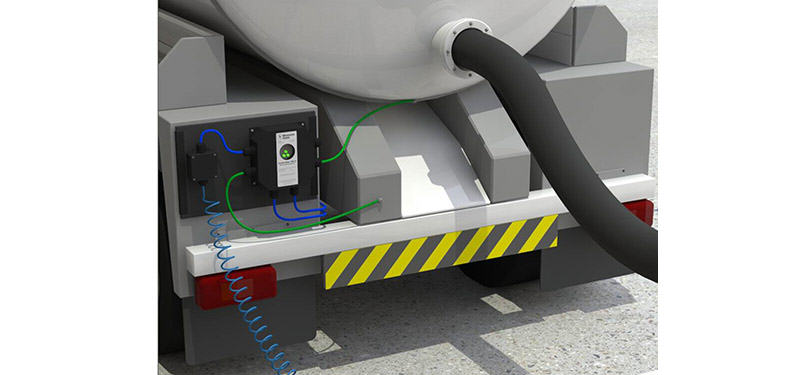

System components

- electronic earthing controller – designed for use in explosion hazard zones,

- spiral cable (with hytrel casing) or reel with cable,

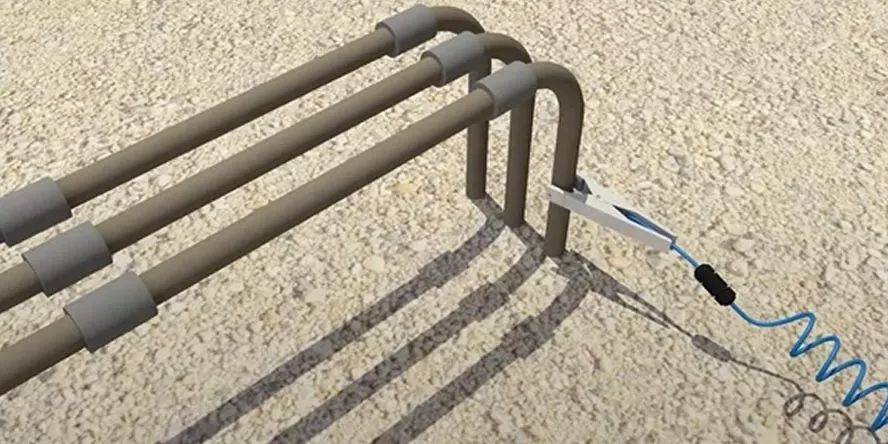

- robust stainless steel clamp with sharp teeth made of tungsten carbide.

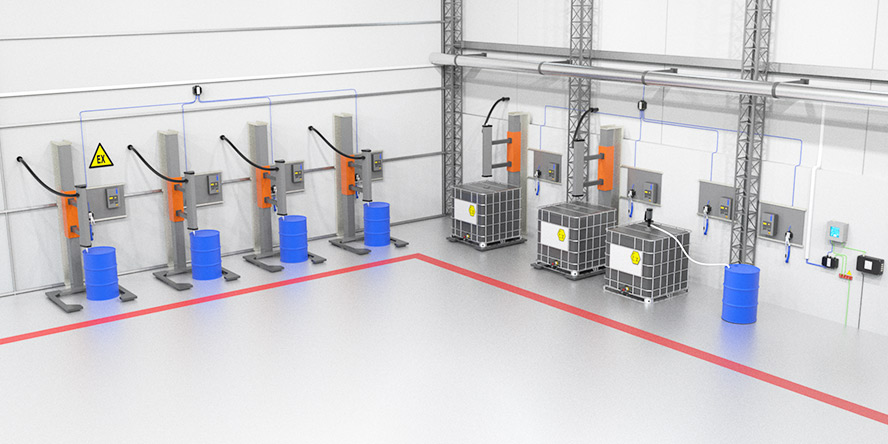

Use SAFELY any structure as grounding

In many cases, stationary devices are used to control the grounding of road tankers. Unfortunately, not every industrial plant or storage base is equipped with such devices. Additionally, due to existing regulations, stationary grounding controllers are installed at distances ranging from several dozen to several hundred meters from storage tanks. Such a situation practically prevents the grounding control of vehicles, which, due to the tasks being performed (e.g., cleaning or maintenance), must be located in the immediate vicinity of storage tanks.

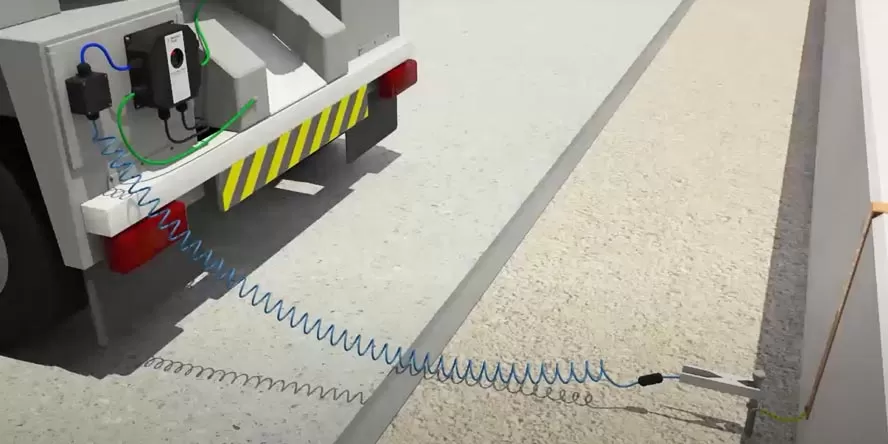

In such situations, it is recommended to use a mobile system that is mounted directly on the vehicle’s structure. This solution allows the grounding to be connected to any metal structure embedded in the ground or to a special bolt that the operator drives into the ground. The system verifies whether the used structure provides proper electrostatic charge dissipation and continuously monitors the vehicle’s connection to the ground. If the connection is lost, the system will inform the operator by changing the color of the light indicator and will halt the process.

Principle of operation

The MGV system verifies the earthing in three steps before issuing permission to start loading/unloading the road tanker:

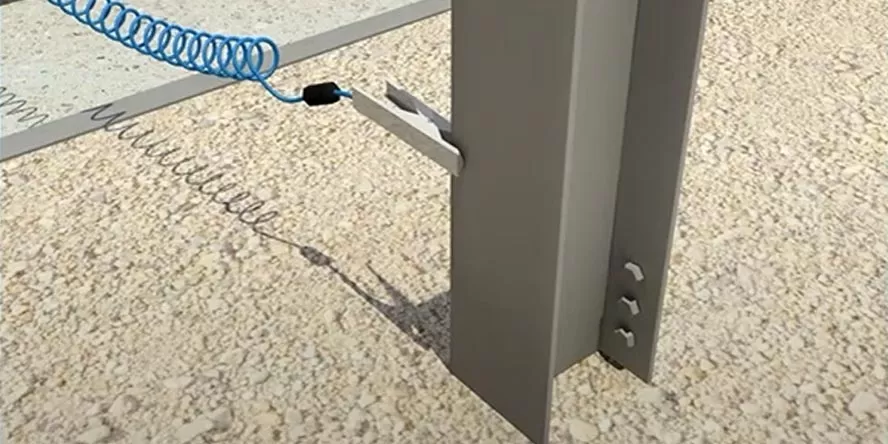

- checks that the fixed connection between the MGV system and the tank structure is correct (this solution ensures that the system is connected to a tank component that effectively receives electrostatic charges from the whole structure and indicates an error when the connection is broken),

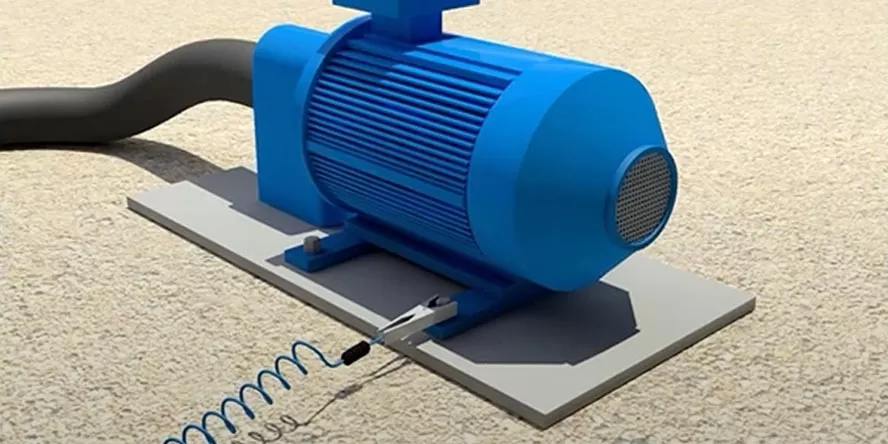

- checks that the clamp is connected to a earth point that allows the charges to be effectively discharged to the ground (it happens that there is no access to the cooper near the place where the reloading is carried out. In such cases it is possible to connect the clamp to another metal component which is buried in the ground – e.g. a lightning conductor or a steel pole. The system will check whether their resistance is less than 10 Ω, and thus whether they are capable of effectively discharging charges to the ground),

- checks that the resistance of the tanker/point circuit during transshipment is below the limit value (the earthing may become broken or damaged during transshipment; such a situation is not acceptable, therefore the system will detect and block the process when the resistance of the tanker/earthing point circuit increases above 10 Ω).

Why use an MGV earthing controller?

During transshipment of liquid substances, the structure of road tankers and loading hoses or arms is strongly electrified. If the product being transported is flammable or emits flammable substances, the jump of an electrostatic spark can ignite the so-called explosive atmosphere (i.e. the mixture of gas or vapour of the product being transported with air). In such situations, in accordance with the regulations of the Minister of Economy, the road tanker must be earthed and this state must be monitored throughout the process or the process must be blocked if proper earthed state is lost.