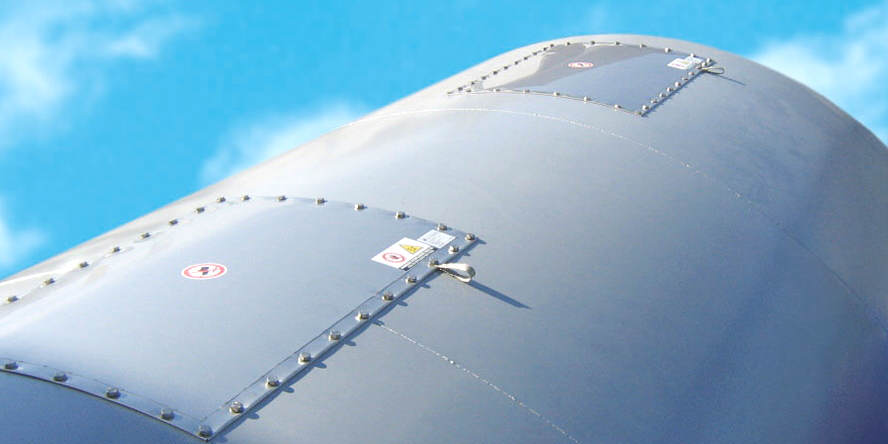

RLE‑S square explosion relief dampers

The RLE-S square explosion relief dampers provide protection from explosion. The most usual applications include protection of filters, electrostatic precipitators and drying units against damage from explosion. The damper system closes itself following an explosion relief action and isolates the flow of air.

Applications

- Protection of filters, electrostatic precipitators and drying units against damage from explosion by controlled relief and venting of explosion products into the atmosphere;

- Self-closing following an explosion relief action (the damper isolates the flow of air).

Specifications

- The pressure of explosion releases the damper closure from its retaining latches, which opens the damper;

- 80% of the resulting damper recoil force is dampened by the air cushion formed between the explosion relief damper and a steel deflector plate;

- The residual recoil force of the damper is further dispersed by the deflector plates and the damper is closed automatically to isolate the flow of air once the explosion products have been vented;

- Lightweight structure (of aluminium components) which prevent transmission of explosion loads to the protected equipment unit;

- The spring-loaded retaining latch helps set the initial opening pressure of the explosion relief damper (the standard setting is 0.1 barg);

- Each opening action of the explosion relief damper can be remotely indicated by a limit switch;

- The explosion relief damper can optionally feature an electric heater;

- Suitable for horizontal or vertical orientation of installation.