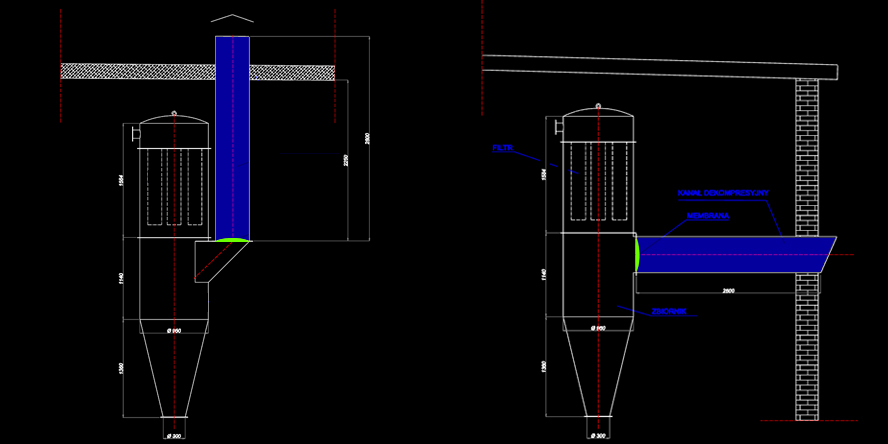

Vigilex VD anti-explosion panels

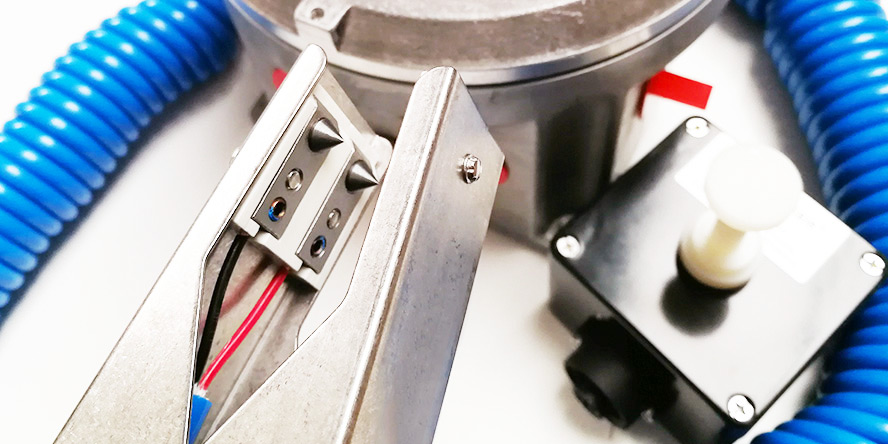

Standard technical data:

- Maximum vacuum resistance 200 mbar (optionally 500 mbar),

- Opening pressure 100 mbar +/- 15% at 20°C,

- Material stainless steel 304L (frame stainless steel 430),

- Mono-layer, convex,

- Frame sealing made of EPDM (from -40°C to 80°C),

- Integrated flange, stainless steel,

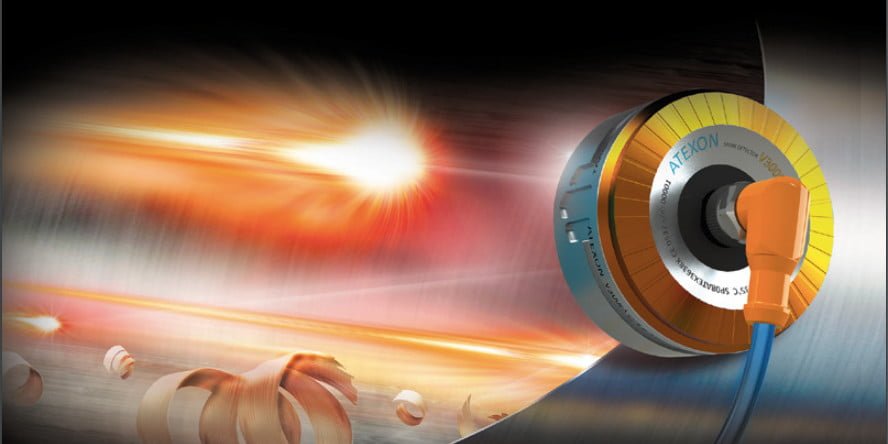

- KST MAX 500 bar x m/s,

- Efficiency index 80% – 100%,

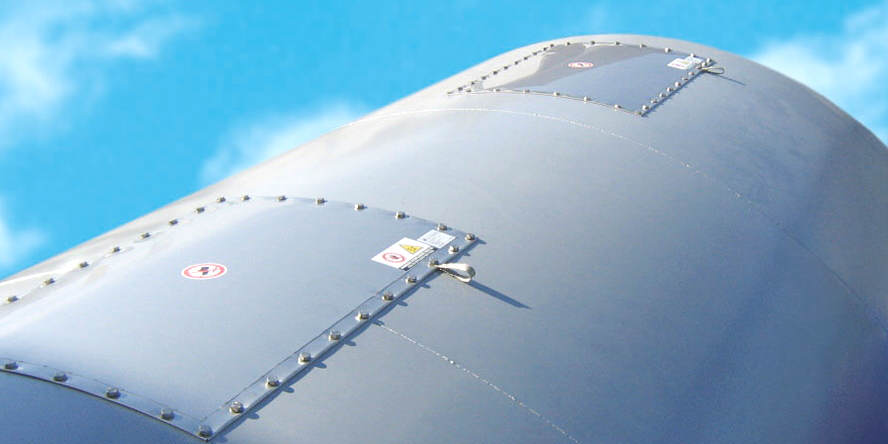

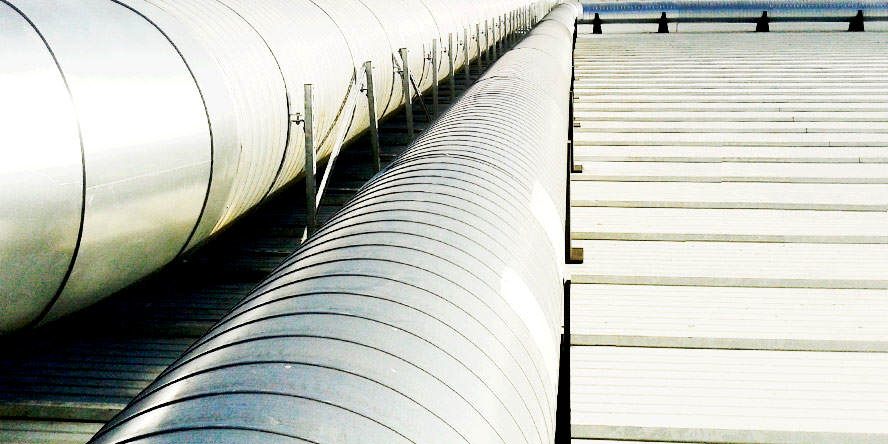

- Possibility of mounting on curved surfaces – curve radius according to order.

Option VD Sanitary:

- Panel material stainless steel 316 L,

- Full frame silicon FDA gasket (-40°+180°C),

- Integrated stainless steel 316L flange.

Rectangular & Square Vigilex VD anti-explosion panels

| Inside dimensions [mm] | Outside dimensions [mm] | Vent area [cm²] |

|---|---|---|

| 150 X 600 | 230 X 680 | 885 |

| 205 X 290 | 285 X 370 | 580 |

| 220 X 420 | 300 X 500 | 900 |

| 229 X 229 | 310 X 310 | 515 |

| 229 X 305 | 310 X 386 | 680 |

| 247 X 610 | 327 X 690 | 1450 |

| 305 X 457 | 386 X 538 | 1380 |

| 340 X 385 | 404 X 449 | 1280 |

| 340 X 440 | 404 X 504 | 1430 |

| 375 X 655 | 460 X 740 | 2445 |

| 410 X 410 | 480 X 480 | 1660 |

| 457 X 890 | 437 X 970 | 4050 |

| 470 X 610 | 550 X 690 | 2800 |

| 490 X 490 | 570 X 570 | 2380 |

| 490 X 590 | 570 X 670 | 2865 |

| 525 X 668 | 630 X 765 | 3400 |

| 586 X 920 | 666 X 1000 | 5360 |

| 610 X 610 | 690 X 690 | 3650 |

| 610 X 1118 | 690 X 1198 | 6750 |

| 645 X 645 | 735 X 735 | 4130 |

| 645 X 1130 | 735 X 1220 | 7250 |

| 653 X 653 | 735 X 735 | 4200 |

| 915 X 1118 | 996 X 1198 | 10000 |

| 920 X 920 | 1000 X 1000 | 8425 |

| 980 X 980 | 1070 X 1070 | 9600 |

| 1020 X 1020 | 1100 X 1100 | 10360 |

Round Vigilex VD anti-explosion panels

| Inside dimensions [mm] | Outside dimensions [mm] | Vent area [cm²] |

|---|---|---|

| Ø 200 | Ø 268 | 310 |

| Ø 250 | Ø 341 | 480 |

| Ø 300 | Ø 390 | 695 |

| Ø 350 | Ø 422 | 955 |

| Ø 400 | Ø 473 | 1250 |

| Ø 450 | Ø 545 | 1580 |

| Ø 500 | Ø 574 | 1935 |

| Ø 600 | Ø 676 | 2790 |

| Ø 700 | Ø 776 | 3830 |

| Ø 750 | Ø 842 | 4400 |

| Ø 800 | Ø 877 | 5005 |

| Ø 900 | Ø 980 | 6335 |

| Ø 980 | Ø 1070 | 7510 |